Cost-Efficient Testing Methods for XXL Rotor Blades

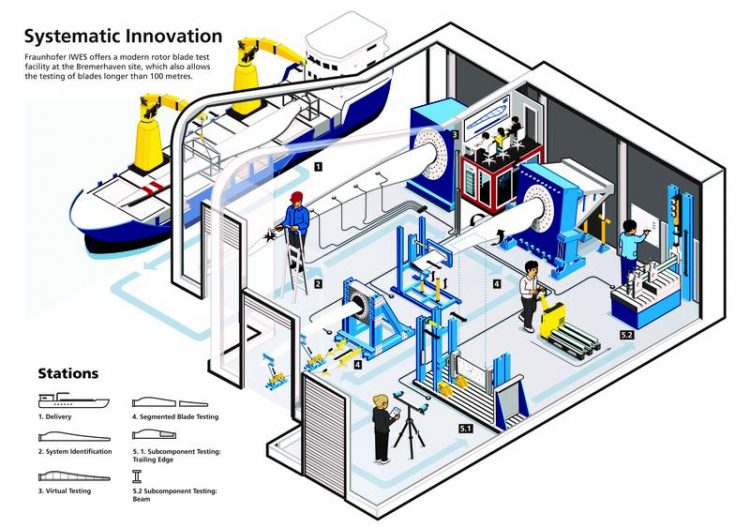

Visualization of project activities: Segment, section, and component testing Fraunhofer IWES

Actual developments have now exceeded the specialists’ expectations: When Fraunhofer IWES opened the first rotor blade testing hall with its 70-meter test bed back in 2009, the maximum length of a rotor blade was just 62.5 meters. This was joined by a second hall in 2011, allowing testing of blades measuring up to 90 meters.

However, blades measuring 100 meters are now already entering their respective testing phases, and these cannot currently be tested at Fraunhofer IWES. But this is going to change in the foreseeable future: Ground will be broken on the new test bench in Bremerhaven by the end of the year, and the facility is expected to start operation in 2021.

The core of the planned test bench will be a new test block measuring 11×11 meters and with the option of being extended to suit higher blade lengths in future if and when required. Moreover, the test bench will comprise the possibility to offer component and segment testing – which is a novelty for the wind industry.

In addition to the higher loads encountered in full-scale blade testing, the duration of the test, indirectly related to the size, represents a further challenge. Moreover, it is not possible to assess all areas of the rotor blade in detail and model them with statistical reliability in full-scale blade testing.

Testing facilities for components and segments as well as the use of new methods can close this gap. They should provide more detailed information on critical rotor blade sections in this respect.

`Large independent test facilities are a major enabler for our upcoming developments of large offshore turbines. New concepts such as component testing and segment testing of blades are extremely interesting for us,` explains Flemming Kløcker Grove, Senior Project Manager at MHI Vestas Offshore Wind.

As the investigation of segments such as the trailing edge of a blade is more cost-effective than full-scale blade testing, it will be possible for manufacturers to perform a number of tests on one component in the future and increase the statistical relevance of the results. In addition, it is possible to induce and understand specific damage mechanisms.

`It’s not just about testing longer blades – we also want to test more intelligently and expand our position as a leading institute for rotor blade tests`, explained Steffen Czichon, Head of Fraunhofer´s Department for Rotor Blades.

The aim of the ´Future Concept Operational Stability Rotor Blades Phase II´ project is to ensure that experimental testing of very long rotor blades remains economically viable for manufacturers. New testing procedures for the investigation of segments and components will offer a better understanding of critical areas and thus increase the informative value of the tests considerably. This information can be employed to design rotor blades even more precisely in the future, thereby saving on both weight and costs.

Breakdown of funding for the project

“Future Concept Operational Stability Rotor Blades Phase II”:

Hall construction:

German Federal Ministry of Education and Research (BMBF) and the State of Bremen/ERDF, € 3.4 million altogether

Test bench construction:

German Federal Ministry for Economic Affairs and Energy (BMWi), €8 million

Method development work packet – State of Bremen/ERDF: € 253,000

Dipl.-Ing. Moritz Bätge, moritz.baetge@iwes.fraunhofer.de

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…