Artificial intelligence accelerates discovery of metallic glass

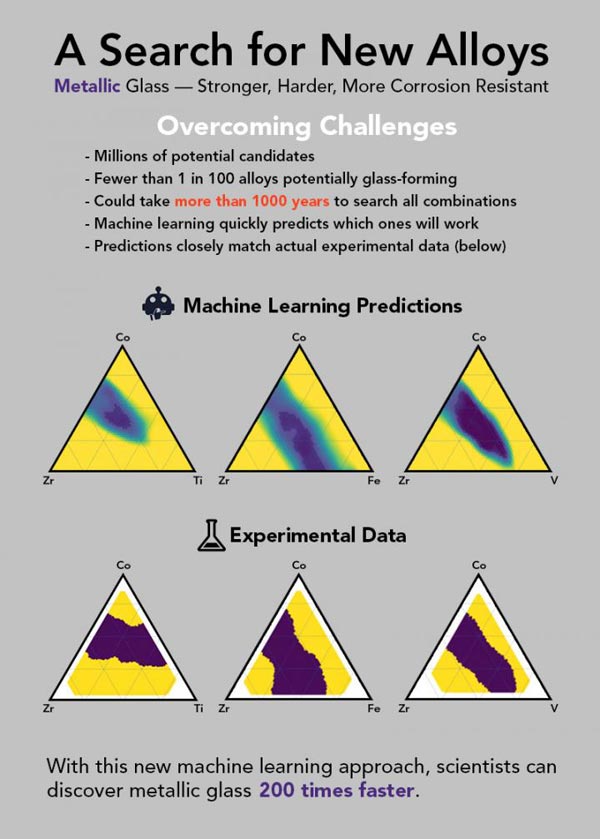

With new, artificial intelligence approach, scientists discovered metallic glass 200 times faster than with an Edisonian approach. Credit: SLAC National Accelerator Laboratory

If you combine two or three metals together, you will get an alloy that usually looks and acts like a metal, with its atoms arranged in rigid geometric patterns.

But once in a while, under just the right conditions, you get something entirely new: a futuristic alloy called metallic glass. The amorphous material's atoms are arranged every which way, much like the atoms of the glass in a window. Its glassy nature makes it stronger and lighter than today's best steel, and it stands up better to corrosion and wear.

Although metallic glass shows a lot of promise as a protective coating and alternative to steel, only a few thousand of the millions of possible combinations of ingredients have been evaluated over the past 50 years, and only a handful developed to the point that they may become useful.

Now a group led by scientists at the Department of Energy's SLAC National Accelerator Laboratory, the National Institute of Standards and Technology (NIST) and Northwestern University has reported a shortcut for discovering and improving metallic glass — and, by extension, other elusive materials — at a fraction of the time and cost.

The research group took advantage of a system at SLAC's Stanford Synchrotron Radiation Lightsource (SSRL) that combines machine learning — a form of artificial intelligence where computer algorithms glean knowledge from enormous amounts of data — with experiments that quickly make and screen hundreds of sample materials at a time. This allowed the team to discover three new blends of ingredients that form metallic glass, and to do it 200 times faster than it could be done before.

The study was published today, April 13, in Science Advances.

“It typically takes a decade or two to get a material from discovery to commercial use,” said Chris Wolverton, the Jerome B. Cohen Professor of Materials Science and Engineering in Northwestern's McCormick School of Engineering, who is an early pioneer in using computation and AI to predict new materials. “This is a big step in trying to squeeze that time down. You could start out with nothing more than a list of properties you want in a material and, using AI, quickly narrow the huge field of potential materials to a few good candidates.”

The ultimate goal, said Wolverton, who led the paper's machine learning work, is to get to the point where a scientist can scan hundreds of sample materials, get almost immediate feedback from machine learning models and have another set of samples ready to test the next day — or even within the hour.

Over the past half century, scientists have investigated about 6,000 combinations of ingredients that form metallic glass. Added paper co-author Apurva Mehta, a staff scientist at SSRL: “We were able to make and screen 20,000 in a single year.”

Just getting started

While other groups have used machine learning to come up with predictions about where different kinds of metallic glass can be found, Mehta said, “The unique thing we have done is to rapidly verify our predictions with experimental measurements and then repeatedly cycle the results back into the next round of machine learning and experiments.”

There's plenty of room to make the process even speedier, he added, and eventually automate it to take people out of the loop altogether so scientists can concentrate on other aspects of their work that require human intuition and creativity. “This will have an impact not just on synchrotron users, but on the whole materials science and chemistry community,” Mehta said.

The team said the method will be useful in all kinds of experiments, especially in searches for materials like metallic glass and catalysts whose performance is strongly influenced by the way they're manufactured, and those where scientists don't have theories to guide their search. With machine learning, no previous understanding is needed. The algorithms make connections and draw conclusions on their own, which can steer research in unexpected directions.

“One of the more exciting aspects of this is that we can make predictions so quickly and turn experiments around so rapidly that we can afford to investigate materials that don't follow our normal rules of thumb about whether a material will form a glass or not,” said paper co-author Jason Hattrick-Simpers, a materials research engineer at NIST. “AI is going to shift the landscape of how materials science is done, and this is the first step.”

Experimenting with data

In the metallic glass study, the research team investigated thousands of alloys that each contain three cheap, nontoxic metals.

They started with a trove of materials data dating back more than 50 years, including the results of 6,000 experiments that searched for metallic glass. The team combed through the data with advanced machine learning algorithms developed by Wolverton and Logan Ward, a graduate student in Wolverton's laboratory who served as co-first author of the paper.

Based on what the algorithms learned in this first round, the scientists crafted two sets of sample alloys using two different methods, allowing them to test how manufacturing methods affect whether an alloy morphs into a glass. An SSRL x-ray beam scanned both sets of alloys, then researchers fed the results into a database to generate new machine learning results, which were used to prepare new samples that underwent another round of scanning and machine learning.

By the experiment's third and final round, Mehta said, the group's success rate for finding metallic glass had increased from one out of 300 or 400 samples tested to one out of two or three samples tested. The metallic glass samples they identified represented three different combinations of ingredients, two of which had never been used to make metallic glass before.

###

The study was funded by the US Department of Energy (award number FWP-100250), the Center for Hierarchical Materials Design and the National Institute of Standards and Technology (award number 70NANB14H012).

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…