An innovative catalyst with Pt, Re and SnO2 nanoparticles as anode material in ethanol fuel cells

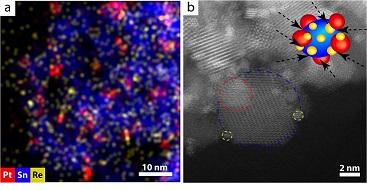

Ternary Pt/Re/SnO2/C catalyst: a) EDS map confirming the presence of Pt (red), SnO2 (blue) and Re (yellow); and b) high-resolution HAADF STEM high-resolution image confirming physical contact between Pt, Re and SnO2 nanoparticles, obtained by using a transmission electron microscope. The upper right corner shows a scheme of SnO2 nanoparticles decorated with metallic Pt and Re nanoparticles. Black dashed arrows indicate places of physical contact between individual nanoparticles. (Source: IFJ PAN) Source: IFJ PAN

One of the biggest challenges modern science faces today is the development of new, efficient and environmentally friendly technologies for converting chemical energy into electricity. Ethanol fuel cells are becoming such an alternative source of energy.

Ethanol seems to be the ideal fuel of the future, because, compared to methanol or hydrogen, it has significantly lower toxicity, poses no problems or threats in storage and transport, and can also be obtained from biomass.

However, the catalysts used in direct ethanol fuel cells (DEFCs) are not sufficiently effective and mainly produce by-products instead of the expected ethanol final product, such as carbon dioxide. These substances strongly adsorb on the surface of platinum, which is the most commonly used catalyst.

As a result, they block the catalytically active sites preventing a further reaction, thus causing so-called catalyst poisoning and lowering the overall efficiency of the device. Therefore, the key challenge is to develop the appropriate type of catalysts.

Platinum and platinum-based catalysts are widely used in DEFCs. Ethanol adsorption occurs on the platinum surface, which triggers its oxidation reaction (Ethanol Oxidation Reaction – EOR). Poisoning problems can be solved by adding other components to platinum, such as metallic rhodium and tin oxides, which improve the efficiency of the EOR because they play a unique and individual role in the ethanol oxidation pathway.

The function of rhodium is to split the carbon-carbon bond in the ethanol molecule, while tin dioxide provides hydroxyl groups for oxidizing intermediates and helps unblock the inactive surface of platinum. In addition to rhodium and tin, elements such as Ru, Ir, Cu, Fe, Co, Ni and many others are also used.

A ternary nanocatalyst containing platinum and rhodium nanoalloys deposited on tin oxide, which is currently considered one of the most efficient and selective configurations in the ethanol oxidation reaction, has also been extensively studied. It is also suggested that physical contact between nanoparticles plays a crucial role.

Scientists from the Department for Functional Nanomaterials at the Institute of Nuclear Physics of the Polish Academy of Sciences, led by Prof. Eng. Magdalena Parlinska-Wojtan, undertook the task of designing and synthesizing a new material, which could play the role of an anode catalyst. For this purpose, they decided to analyze the effect of rhenium, used as one of the three catalyst components, on improving the efficiency of the EOR.

Moreover, the researchers assumed that by using intermolecular interactions and electrokinetic potential measurements, it would be possible to assemble the separately synthesized Pt, Re and SnO2 nanoparticles into double and triple combinations to ensure their physical contact.

This assembling is possible due to the opposite values of the electrokinetic potential of each type of nanoparticles. While performing stability studies, the researchers also focused on the durability of the catalyst because the degradation of nanocatalyst components is a serious factor limiting the stability and commercialization of catalysts.

“In the first stage of our work, we optimized the processes for obtaining individual nanoparticles: platinum, rhenium and tin oxide, which were intended to be the components of an anode catalyst,” says Dr. Eng. Elzbieta Drzymala from IFJ PAN, the leading author of the scientific publication, describing the details of the conducted studies.

“Then, using intermolecular interactions, we put individually synthesized nanoparticles together to ensure physical contact between them. In this way, we obtained binary and ternary nanoparticle combinations, which were then deposited on carbon substrates with even distribution to provide ethanol molecules with the best access to active surfaces.

The next step was to study the electrochemical properties of selected binary and ternary combinations given their potential use as anode material in ethanol fuel cells. Finally, we compared the results of our work with a commercial platinum catalyst.”

The obtained results turned out to be very important and encouraged further research on this type of materials. The catalyst developed by the IFJ PAN group made of Pt, Re and SnO2 nanoparticles can be successfully used as an anode catalyst in DEFCs. Analyzes carried out with transmission electron microscopy (TEM) in combination with EDS spectroscopy confirmed the physical contact between the nanoparticles forming the ternary Pt/Re/SnO2/C catalyst (see figure). It has been experimentally proven by voltammetric techniques that this ternary catalyst exhibits more than ten times higher activity in the ethanol oxidation reaction compared to a commercial platinum catalyst.

Besides, it has been shown that the Pt/Re/SnO2/C catalyst features the best stability – after testing, it preserved nearly 96 % of the electrochemically active surface (compared to 12 % for the commercial catalyst). It is also important that the ternary catalyst shows the lowest value of onset potential – the value of the initial oxidation potential is almost 0.3 V lower compared to a commercial platinum catalyst.

Thus, the use of rhenium as the third component and connecting nanoparticles in such a way that they remain in physical contact generated the desired effect of improving the efficiency of the EOR.

“Our further research will continue to focus on fuel cell catalysts,” explains Dr. Eng. Drzymala. “However, going a step further, we would like to solve the economic issues and develop a catalytic system with better or at least comparable properties but without the addition of platinum. I believe that the use of platinum-free nanoparticles decorated with small 2-nanometer SnO2 nanoparticles as components of such a catalyst will bring us closer to creating a fully functional material for the fuel cell anode. I hope that the catalyst without platinum will be synthesized soon at the Department for Functional Nanomaterials at the Institute of Nuclear Physics of the Polish Academy of Sciences.”

###

The Henryk Niewodniczanski Institute of Nuclear Physics (IFJ PAN) is currently the largest research institute of the Polish Academy of Sciences. The broad range of studies and activities of IFJ PAN includes basic and applied research, ranging from particle physics and astrophysics, through hadron physics, high-, medium-, and low-energy nuclear physics, condensed matter physics (including materials engineering), to various applications of methods of nuclear physics in interdisciplinary research, covering medical physics, dosimetry, radiation and environmental biology, environmental protection, and other related disciplines. The average yearly yield of the IFJ PAN encompasses more than 600 scientific papers in the Journal Citation Reports published by the Clarivate Analytics. The part of the Institute is the Cyclotron Centre Bronowice (CCB) which is an infrastructure, unique in Central Europe, to serve as a clinical and research centre in the area of medical and nuclear physics. IFJ PAN is a member of the Marian Smoluchowski Kraków Research Consortium: “Matter-Energy-Future” which possesses the status of a Leading National Research Centre (KNOW) in physics for the years 2012-2017. In 2017 the European Commission granted to the Institute the HR Excellence in Research award. The Institute is of A+ Category (leading level in Poland) in the field of sciences and engineering.

CONTACTS:

Dr. Eng. Elzbieta Drzymala

Institute of Nuclear Physics of Polish Academy of Sciences

tel. +48 12 662 8390

e-mail: elzbieta.drzymala@ifj.edu.pl

SCIENTIFIC PAPERS:

1.

Elzbieta Drzymala, Grzegorz Gruzel, Joanna Depciuch, Miroslawa Pawlyta, Mikolaj Donten and Magdalena Parlinska-Wojtan “Ternary Pt/Re/SnO2/C catalyst for EOR: Electrocatalytic activity and durability enhancement”

Nano Research 2020, 13(3): 832-842

DOI: 10.1007/s12274-020-2704-1

LINKS:

The website of the Institute of Nuclear Physics of the Polish Academy of Sciences

Press releases of the Institute of Nuclear Physics of the Polish Academy of Sciences

IMAGES:

IFJ20200624_foto1s.jpg HR: http://press.

Ternary Pt/Re/SnO2/C catalyst: a) EDS map confirming the presence of Pt (red), SnO2 (blue) and Re (yellow); and b) high-resolution HAADF STEM high-resolution image confirming physical contact between Pt, Re and SnO2 nanoparticles, obtained by using a transmission electron microscope. The upper right corner shows a scheme of SnO2 nanoparticles decorated with metallic Pt and Re nanoparticles. Black dashed arrows indicate places of physical contact between individual nanoparticles. (Source: IFJ PAN)

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…