Direct ReSi – Si-recovery from recycling of SiC-slurry

The production of Si-wafers for solar cells or semiconductors still utilizes wire saw cutting to turn silicon bricks into wafers. The actual cutting is performed by the cutting slurry, a suspension of silicon carbide (SiC) in cooling fluid. Recycling of the waste slurry, which contains silicon (Si) and SiC as valuable materials, can generate cost savings. The demand for Si-wafers, and therefore the need for cost-effective and efficient recycling continuously increases.

After separation of the coarse SiC-particles, the remaining mixture of Si and SiC is treated with acids. Si is concerted into Chlorosilane, and the remaining SiC recovered. The Chlorosilane can be feed into the production process for silicon.

Further Information: PDF

PROvendis GmbH

Phone: +49 (0)208/94105 10

Contact

Dipl.-Ing. Alfred Schillert

Media Contact

All latest news from the category: Technology Offerings

Newest articles

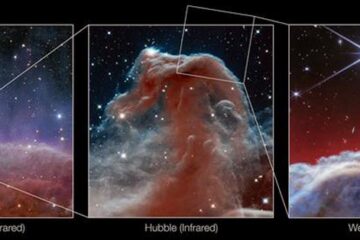

Webb captures top of iconic horsehead nebula in unprecedented detail

NASA’s James Webb Space Telescope has captured the sharpest infrared images to date of a zoomed-in portion of one of the most distinctive objects in our skies, the Horsehead Nebula….

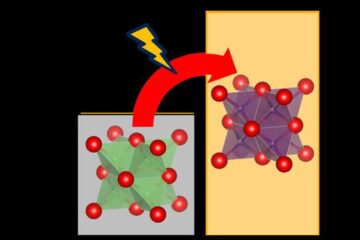

Cost-effective, high-capacity, and cyclable lithium-ion battery cathodes

Charge-recharge cycling of lithium-superrich iron oxide, a cost-effective and high-capacity cathode for new-generation lithium-ion batteries, can be greatly improved by doping with readily available mineral elements. The energy capacity and…

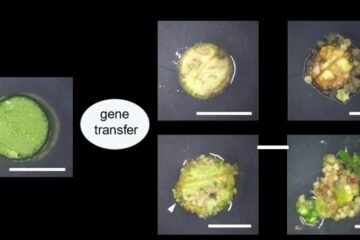

Novel genetic plant regeneration approach

…without the application of phytohormones. Researchers develop a novel plant regeneration approach by modulating the expression of genes that control plant cell differentiation. For ages now, plants have been the…