High octane waste: New catalyst and reactor technologies combine for efficient waste to fuel production

With the acquisition of Velocys Inc., a designer and developer of microchannel process technology, catalyst developer Oxford Catalysts, has taken a big step towards bringing these two technologies together to make small scale FT microchannel reactors a viable option for the commercial production of diesel and jet fuels. Velocys now owns, or has licences to, the largest microchannel reactor patent portfolio in the world.

Microchannel reactors are the best candidates for producing liquid fuels from sources such as agricultural waste, municipal solid waste and associated/flare gas, as well as from stranded gas, and coal. This is because they offer a way to reduce the size and cost of the chemical processing hardware, while still enabling efficient and precise temperature control, leading to higher throughput and conversion. Like the microelectronics technology that revolutionised the computer industry, microchannel technology shrinks processing hardware, while at the same time improving its performance.

To maximise the benefits they offer, microchannel reactors require an FT catalyst with activities an order of magnitude higher than conventional catalysts. The latest FT catalyst developed by Oxford Catalysts fits this bill exactly, and is specifically optimised for Velocys’ microchannel reactor design.

The FT reaction has the potential to reduce the carbon footprint of transportation fuels produced from organic waste by up to 90% compared to fossil fuels. By combining the expertise of the two companies, Oxford Catalysts hopes to refine the processes required to make the commercial production of liquid fuels from a variety of waste sources an economic and environmentally friendly proposition.

Derek Atkinson, Business Development Director, Oxford Catalysts says:

“By working more closely together to optimise and intensify the FT process we will be able to make the production of liquid fuels from a wide variety of sources a more practical proposition. This will also help governments to achieve their carbon reduction commitments.”

Jeff McDaniel, Business Development Director, Velocys says:

“By combining our two innovative technologies we believe that we are now in an outstanding position to move forward towards the goal of producing liquid fuels that are cleaner and have a lower carbon footprint.”

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

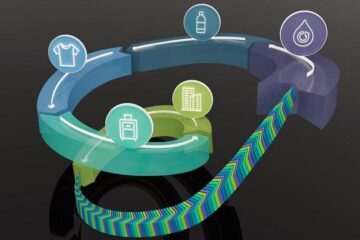

Roadmap to close the carbon cycle

A holistic approach to reach net-zero carbon emissions across the economy. A major approach to achieving net-zero carbon emissions relies on converting various parts of the economy, such as personal…

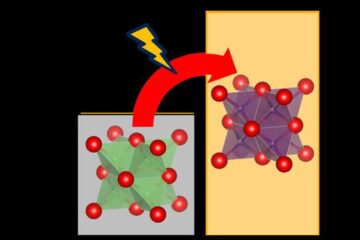

Cost-effective, high-capacity, and cyclable lithium-ion battery cathodes

Charge-recharge cycling of lithium-superrich iron oxide, a cost-effective and high-capacity cathode for new-generation lithium-ion batteries, can be greatly improved by doping with readily available mineral elements. The energy capacity and…

New regulator of eating behaviour identified

The rapidly escalating prevalence of overweight and obesity poses a significant medical challenge worldwide. In addition to people’s changing lifestyles, genetic factors also play a key role in the development…