Sensor + Test 2015: Cost-effective production of magnetic sensors

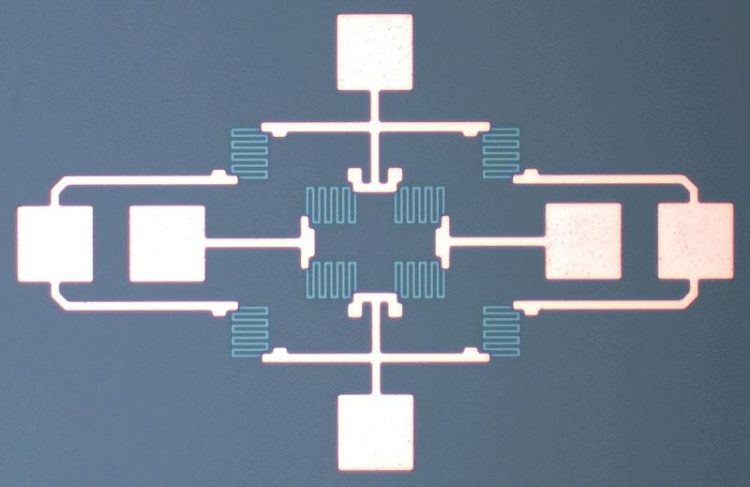

View from above of the prototype of a two-dimensional magnetic sensor. © Fraunhofer ENAS

Where did you have to go? Turn right here – or was it the next turn? A glance at the smart-phone helps: Various apps provide maps and turn them in the right direction, adjusting them to north. Navigation devices are equally »clever«: They too show the right direction even before the car sets off.

This is made possible by a magnetic sensor. It establishes how the device is being held in relation to the earth’s magnetic field. The market is highly competitive: Every cent counts in the price of the sensors. Until now, manufacturers have relied on several cheap one-dimensional sensors. The disadvantage: They are less sensitive and do not work as accurately as two-dimensional models.

In future however, compact two-dimensional sensors could find their way into smart-phones. Researchers from the Fraunhofer Institute for Electronic Nano Systems ENAS, in Chemnitz have optimized the corresponding manufacturing process. »The costs and manufacturing time for two-dimensional magnetic field sensors drop by half«, says Dr. Olaf Ueberschär, group manager at the ENAS.

The reason for this drop in costs lies in the method of production: The scientists produce the sensors from one piece of material – hence in a totally different way than ever before. Because even a one-dimensional sensor needs two microelectronic half-bridges, whose applied magnetic fields point in opposite directions.

As the basic materials specify a magnetization direction, meaning that the magnetic field within them is already aligned, two different pieces of material used to have to be joined – an elaborate and also expensive procedure. Two half-bridge sensors or four pieces of material were required for two-dimensional sensors.

»For the first time we are able to produce not only the full bridges, but also the two-dimensional sensors monolithically – from one piece«, Ueberschär adds. For this purpose, the researchers separate a layer of material off a wafer and etch the desired structure out. The trick lies in the subsequent laser treatment: This enables the scientists to adjust the preferred magnetic directions at will.

Another advantage: The new sensor is not even quite a square millimeter in size, thus being only about half the size as former models. The smaller the mini-chips are, the more applications they are suitable for. For example for magnetic field cameras, containing numerous sensors in several lines and columns, recording magnetic data. If a high resolution is to be achieved, the sensors must be as small as possible – only then do they fit in close proximity to one another and do not mutually interfere.

Magnetic sensor technology is not restricted to smart-phones. It is used wherever adverse ambient conditions prevail and other measurement methods would fail – for instance in fluids or hot oil baths. They are also found in cars, for example in fully electronic gear levers such as are installed in newer vehicles in the center console or on the steering wheel. And in medical diagnostics they are used to trace tropical diseases and other viruses and bacteria.

Experts will present prototypes of the two-dimensional sensors at the Sensor + Test trade fair from May 19 to 21, 2015 in Nuremberg (Hall 12, Booth 12-531 / 12-537). It will however take about another year before the sensors can actually be used in products.

Media Contact

All latest news from the category: Trade Fair News

Newest articles

Sensor measures oxygen content of breath

Oxygen saturation in the blood that is either too low or too high can cause physical harm or even death. This is why patients’ oxygen concentraions are monitored continuously in…

Laser immersion probe for smart inline monitoring of water and wastewater

A new type of laser-based immersion probe, which the Fraunhofer Institute for Laser Technology ILT in Aachen is testing as part of BMBF- and EU-funded projects with industrial partners and…

Webb captures top of iconic horsehead nebula in unprecedented detail

NASA’s James Webb Space Telescope has captured the sharpest infrared images to date of a zoomed-in portion of one of the most distinctive objects in our skies, the Horsehead Nebula….