Fraunhofer IPT and oculavis to present three new software modules for “ODG-R7 Smartglasses”

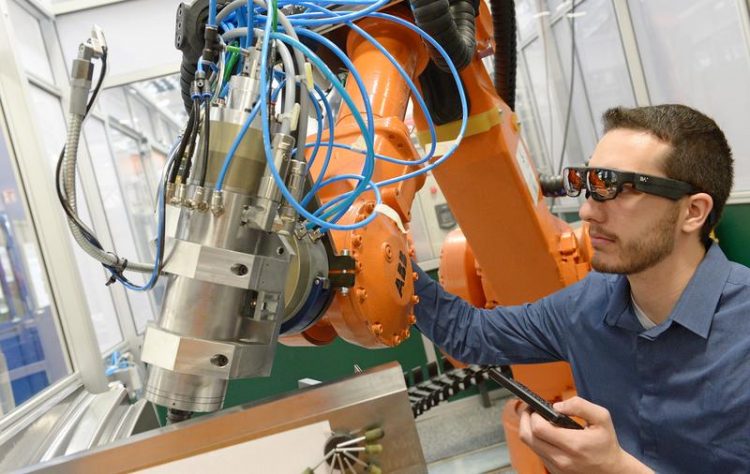

“oculavis.4D-instructor”, “oculavis.pick” and “oculavis.share” software modules permit Augmented Reality (AR) functions to be used in production, logistics and service applications Source: Fraunhofer IPT

The oculavis-software, which runs on a conventional android operating system from version 4.0.4 upward, was developed by the Fraunhofer IPT and will be marketed to industry by oculavis, the up-coming spin-off company as from May 2016.

The oculavis.4D-instructor software module permits animated instructions with 3D-CAD models to be generated and displayed on the smart glasses. This leaves both hands free so that even unskilled workers can assemble or test parts with which they are not yet familiar.

The animations also make the instructions clearer and more easily understandable. By helping to train staff on the shop floor to in this way, smart glasses make a major contribution to accelerating ramp-up processes, particularly in the case of production with a number of variants or where there is a high level of staff turnover.

The oculavis-place software module provides a so-called “Place-to-Augment-solution” for application in logistics: this means that the smart glasses provide the wearer with helpful information in the display as to where a certain part should be placed. This module extends classical pick-solutions applied in logistics to include an additional feature enabling the user to design and put in place swifter, more intuitive logistics processes.

In the service sector, the oculavis.share software module supports videotelophony with new features such as bi-directional annotation, 3D-models and documentation options. When complex tasks are involved, an expert can intervene and instruct the user directly. A tool kit containing sample solutions and pre-defined approaches is on-hand to provide support. The software module thus helps to reduce travel costs and shortens plant and machinery downtimes.

About oculavis

oculavis is a spin-off of the Fraunhofer Institute for Production Technology IPT in Aachen which is currently in the formation phase. The company will be launched in May 2016. The newly formed company is developing a cloud-based software system to connect humans, machines and workpieces along with the corresponding software modules for use with commercially available smart devices. Augmented Reality, or the technique of overlaying information on transparent smart glasses, in the field of view of the wearer, is the principle backed by oculavis. The goal pursued by oculavis is to increase productivity by enhancing information processes in the production environment and to provide a perfect interface for communications between man and production systems.

About Fraunhofer IPT

The Fraunhofer Institute for Production Technology IPT in Aachen brings together many years of knowledge and experience from all fields of production technology. In the areas of process technology, production machines, production quality and metrology as well as technology management, Fraunhofer IPT offers its customers and project partners applied research and development for a connected, adaprice production. The institute's range of services is orientated towards the individual tasks and challenges within certain industries, technologies and product areas, including automotive and supply, energy, life sciences, aviation, mechanical and plant engineering, optics, precision and microtechnology as well as tool and mold making.

Contact

Eike Permin

Fraunhofer Institute for Production Technology IPT

Steinbachstrasse 17

52074 Aachen

Germany

Phone +49 241 8904-452

eike.permin@ipt.fraunhofer.de

www.ipt.fraunhofer.de

Dr. Markus Große Böckmann

oculavis c/o Fraunhofer IPT

Steinbachstrasse 17

52074 Aachen

Germany

Phone +49 160 7978489

grosseboeckmann@oculavis.de

www.oculavis.de (to be launched in May 2016)

This press release and a printable photograph are also available on the internet:

www.ipt.fraunhofer.de/en/Press/Pressreleases/20160420oculavishmi2016.html

http://www.ipt.fraunhofer.de/en/Press/Pressreleases/20160420oculavishmi2016.html

Media Contact

All latest news from the category: Trade Fair News

Newest articles

Microscopic basis of a new form of quantum magnetism

Not all magnets are the same. When we think of magnetism, we often think of magnets that stick to a refrigerator’s door. For these types of magnets, the electronic interactions…

An epigenome editing toolkit to dissect the mechanisms of gene regulation

A study from the Hackett group at EMBL Rome led to the development of a powerful epigenetic editing technology, which unlocks the ability to precisely program chromatin modifications. Understanding how…

NASA selects UF mission to better track the Earth’s water and ice

NASA has selected a team of University of Florida aerospace engineers to pursue a groundbreaking $12 million mission aimed at improving the way we track changes in Earth’s structures, such…