Miniaturized Pinch Valve

<strong>Background</strong><br>

Pinch valves are operated by squeezing a flexible tube in a part of the valve by either moving a separate squeezing device against the tube or by impinging the squeezing part with an actuator. However, with current state of the art valves it is necessary to manually insert the tube between the squeezing device and the counter bearing which is in most cases rather complicated. Besides this, most of the pinch valves are as well pretty large and cannot be used in miniaturized or highly integrated systems. Thus the secure dosing of liquids that contain cells or other solids is with the currently available valves only possible when using exchangeable pinch valves.<br><br> <strong>Technology</strong><br> HScientist at the Technische Universität Berlin have now developed a pinch valve that overcomes the current disadvantages of the state of the art as it can be integrated into existing dosing systems as inexpensive single use valve.<br><br> It allows dosing very little amounts of liquid in a very fast, precise and highly dynamic way. As the valve is modularly constructed it allows an inexpensive mass production via injection molding, is easily adaptable to various applications and can be automatized mounted. Moreover it is uncomplicated to incorporate the valve into existing dosing systems without great effort. <br><br> For further information please see also the following link: http://www.process.vogel.de/index.cfm?pid=7085&pk=336319&print= (article in German) <br><br> <b>Benefits:</b><br> <ul> <li>Injection/ejection also possible under counter pressure</li> <li>Usage of different tube diameters in one valve -> realization as mixing valve possible</li> <li>Valves can directly be flange-mounted or molded </li> <li>Allows fast switching cycles by keeping a very high precision</li> <li>Especially for dosing cell- or solid-containing liquids as there are no cleaning or contamination problems </li> </ul><br> <strong>IP Rights</strong><br> EP and US application with priority on June 2010 <br> <br> <strong>Origin</strong><br> Technische Universität Berlin

Further Information: PDF

ipal GmbH

Phone: +49 (0)30/2125-4820

Contact

Dr. Dirk Dantz

Media Contact

All latest news from the category: Technology Offerings

Newest articles

Targeted use of enfortumab vedotin for the treatment of advanced urothelial carcinoma

New study identifies NECTIN4 amplification as a promising biomarker – Under the leadership of PD Dr. Niklas Klümper, Assistant Physician at the Department of Urology at the University Hospital Bonn…

A novel universal light-based technique

…to control valley polarization in bulk materials. An international team of researchers reports in Nature a new method that achieves valley polarization in centrosymmetric bulk materials in a non-material-specific way…

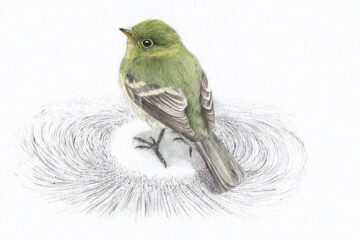

How evolution has optimised the magnetic sensor in birds

The magnetic sense of migratory birds is probably based on the protein cryptochrome 4, and a genetic study has now provided further support for this theory. A team of researchers…