Not-So-Spotty Material Breakthrough

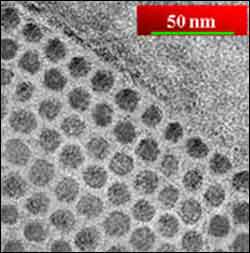

Transmission electron microscope image of nickel nanodots embedded in an aluminum oxide matrix. Credit: Jagdish Narayan and Ashutosh Tiwari, North Carolina State University/NSF Center for Advanced Materials and Smart Structures.

Researchers master self-assembly of novel nanodots

Using pulsed lasers, researchers have coaxed the metal nickel to self-assemble into arrays of nanodots – each spot a mere seven nanometers (seven billionths of a meter) across – one-tenth the diameter of existing nanodots.

Because the method works with a variety of materials and may drastically reduce imperfections, the new procedure may also bolster research into extremely hard materials and efforts to develop ultra-dense computer memory.

The researchers are working with an industry partner to apply the technique to development of next-generation light-emitting diodes (LEDs) – the small, bright lights seen in traffic signals and luxury automobile brake lights. The experimental LEDs are already more efficient than existing devices, potentially lasting decades and using a fraction of the power of fluorescent bulbs.

Jagdish Narayan and Ashutosh Tiwari, both of North Carolina State University and the National Science Foundation’s Center for Advanced Materials and Smart Structures, invented the new materials and manufacturing processes.

They announced their findings in the September, 2004, issue of Nanoscience and Nanotechnology.

Narayan and Tiwari used a pulsed excimer laser to create conditions under which nickel self-assembles into 3-D, ordered arrays within aluminum oxide and titanium nitride matrices. Applying similar techniques to gallium nitride and zinc oxide, the researchers are hoping to further improve the efficiency of their LED devices.

Computer applications are further away, as many additional hurdles need to be cleared before the nanodots become actual chips. However, since every nickel-metal nanodot could theoretically store a single bit of information, the researchers believe that a one-inch chip using that technology could eventually store 10 Terabits of data.

According to the researchers, the chip would theoretically have several hundred times more storage than conventional microchips of the same size. Five Terabits could fit on, coincidentally, a nickel. If nanodot memory chips eventually succeed, the entire contents of the Library of Congress could fit onto a pocket full of “change.”

From the researchers:

“The grand challenge is to build, efficiently and reliably, a nanostructure using nanounits. But nature doesn’t like to create nano-sized units of uniform size—they are at a higher energy state.” – Jagdish “Jay” Narayan, John C. C. Fan Family Distinguished Chair in Materials Science at North Carolina State University and Director, NSF Center for Advanced Materials and Smart Structures

“Controlled processing and self-assembly in three dimensions are required because you cannot create these structures and then assemble them. They are too small. So to be able to use this technology, you must have self-assembly and it must be 3-D.” – Jagdish “Jay” Narayan

“In the past we could make only one-layer structures and 3-D self-assembly wasn’t possible. We couldn’t control the medium. Now, with this development we can control the medium and do 3-D self-organization. More importantly we can change the size in different layers and can change the functionality at different depths.” – Jagdish “Jay” Narayan

“The research provides the basic framework for nanostructured materials for information storage, spin transistors, single-electron transistors and hydrid devices, superhard coatings, and novel biomaterials.” – Jagdish “Jay” Narayan

“In the 6-10 nm dots created so far, we have the ability to control the spin patterns – the spin is what stores the bit of information. Assuming a 7nm magnetic nanodot will store one bit of information, we can achieve over 10 trillion bits per square inch, which is close to 500 times the existing storage density.” – Jagdish “Jay” Narayan

From experts at NSF:

“Narayan has used the basic concepts of self-assembly to create a 3-D array of nanodots which may have significant applications in lighting, lasers, spintronics, and optical devices. If developed for practical applications in the next 2-3 years, the nanodot lighting systems may have significant environmental, economic and energy-saving advantages.” – Mihail C. Roco, Senior Advisor for Nanotechnology, NSF

“The study shows the importance of basic research and encouraging technical innovation. This device is part of the first generation of passive nanostructures and illustrates how one might exploit new phenomena and behavior of materials at the nanoscale for economic advantage.” – Mihail C. Roco

“In a way, this is an illustration of a general objective of United States’ National Nanotechnology Initiative (NNI) – the systematic control of the nanoscale in order to obtain new properties and functions.” – Mihail C. Roco

“We are creating infrastructure: NCSU has established a strength in the area of nanostructured materials, and at this moment, we can see several results that weren’t initially planned.” – Mihail C. Roco

“The expansion of infrastructure for nanoscale research has created a huge base of scientific discovery and potential technological development. A similar trend can be seen in education. From 5 universities with graduate programs in 1999, we now have about 270 academic institutions with undergraduate and graduate programs related to nanoscale science and engineering.” – Mihail C. Roco

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…