New way to make nanoscale circuits is discovered

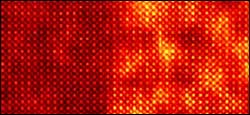

An electron microscope image of a junction between bulk strontium titanate (left) and oxygen-deficient strontium titanate (right). Each bright-orange blob is a cluster of "oxygen vacancies" -- areas of missing atoms. The larger red dots are the strontium atoms and the smaller ones are the titanium atoms. Cornell Center for Materials Research

Time is fast running out for the semiconductor industry as transistors become ever smaller and their insulating layers of silicon dioxide, already only atoms in thickness, reach maximum shrinkage. In addition, the thinner the silicon layer becomes, the greater the amount of chemical dopants that must be used to maintain electrical contact. And the limit here also is close to being reached.

But a Cornell University researcher has caused an information industry buzz with the discovery that it is possible to precisely control the electronic properties of a complex oxide material — a possible replacement for silicon insulators — at the atomic level. And this can be done without chemicals. Instead, the dopant is precisely nothing.

In a paper in a recent issue of Nature (Aug. 5, 2004), David Muller, associate professor of applied and engineering physics at Cornell, and his collaborator, Harold Hwang of the University of Tokyo, report that by removing oxygen atoms from layers in thin films of the oxide strontium titanate, they can precisely control the conducting ability of the material by creating empty spaces, or vacancies, that act as electron-donating dopants. And they have used a scanning transmission electron microscope (STEM) to tell exactly where the missing atoms are in the material.

Across the semiconductor industry, such complex oxides are being sought as a replacement for silicon. The roadblock is that all the oxides tested easily lose a few oxygen atoms, making them leaky and defective when exposed to electric fields, typically stronger than those inside a lightning bolt.

“The important parts of the work are actually being able to see vacancies buried inside the material,” says Muller. “From a materials analysis point of view, that’s very important. The reason is that missing atoms can change the properties of a material very dramatically.” He adds, “We have been able to show that we can stop on a dime in controlling where you put these vacancies.”

In an accompanying commentary to the Nature article called “The value of seeing nothing,” Jochen Mannhart of the University of Augsburg, Germany, and Darrell G. Schlom of Pennsylvania State University, observe that the research by Muller and his colleagues “greatly broadens the options available for manipulating the electronic properties of oxides” at the nanometer scale. A nanometer is the width of three silicon atoms.

Strontium titanate is a titanium-containing material, known commercially as Lustigem, that was once popular as a diamond substitute. It is the simplest of the complex oxides and the one that can be made in the largest quantities. “The big problem with doing any work with oxides is that they form vacancies very easily,” says Muller. “And generally this was viewed as a bad thing because the vacancies acted as dopants that couldn’t be controlled.”

In his Tokyo laboratory, Hwang used a popular research technique called pulsed laser ablation, in which thin films of oxide materials are deposited layer by layer in a vacuum chamber. The atoms were deposited on the material in dribbles; in fact one laser blast deposited only 1/20th of a layer of the material. In this way layers of the material were built up, some only one atom thick. When Hwang decided to deposit a layer without atoms — with vacancies — he reduced the oxygen pressure inside the vacuum chamber. When atoms were laid down, says Muller, the process happened at great speed so that the atoms were “frozen into place” and thus lacked the energy to break their bonds and move into the next layer.

At Cornell, Muller used the STEM to identify exactly where each vacancy — that is, the absence of one atom — was in the layers within the strontium titanate. The emptiness itself was invisible, but the clusters of atoms around the vacancy caused a telltale excess scattering of electrons.

“This is the first step in making devices from strontium titanate,” says Muller. “The question we now have to answer is, what happens if you pass huge currents through these materials?” Generally, though, he says, the ability to detect vacancies at the single-atom level is going to be very important for “debugging” these new semiconductor materials “because the problem is that vacancies at such low concentrations don’t show up in many of the traditional physical characterization methods.”

Does this research mean that a new era of manipulating the electronic properties of oxides for semiconductors at the nano scale is close at hand? “I think we can do it now much better than we could before,” says Muller. “We can tell what’s happening to every atom in the system, whereas before you knew on average if things worked out or if they didn’t. Now you can go out and identify the culprits at fault.”

Muller and Hwang began their research at Bell Laboratories, Lucent Technologies. Their continuing research at Cornell was supported by the National Science Foundation-funded Cornell Center for Materials Research (CCMR). Their other collaborators on the Nature paper were John Grazul, co-manager of the Electron and Optical Microscopy Facility at CCMR; Naoyuki Nakagawa of the University of Tokyo; and Akira Ohtomo of Tohoku University, Japan.

Media Contact

More Information:

http://www.cornell.eduAll latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…