Spying on a Cell – New Nanosensors a Body Can Live With

For two decades, chemists have been making great strides in analyzing the biological functions that drive living cells. But many biological substances still remain undetectable.

That will soon change, thanks to a biological sensor being developed by University of Arizona chemists. Their new sensor platform has many capabilities that current ones lack.

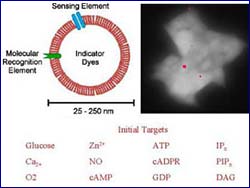

Most intracellular sensors are made from hard plastics (polymers). The plastic is formed into solid, nanometer-sized, BB-like beads, which are doped with chemicals. These chemicals make them sensitive to a variety of ions and molecules. But scientists can only detect intracellular compounds that react optically with these chemicals.

Current biological sensors have several other drawbacks. Imaging dyes and proteins, fiber optics sensors, and coated nano-sized beads can disrupt cellular processes. In addition, they sometimes break down chemically or can be toxic. They also can’t reveal the kinds of chemical processes occurring or their rates of reaction in real time. And they can’t detect large molecules, such as proteins.

“Our new technology takes advantage of some very specific and useful biology,” said UA chemist Craig Aspinwall. “It’s the ability of ions, molecules or groups of molecules to interact with certain proteins. We can use those proteins to report the presence of specific ions and molecules.”

Aspinwall takes an unconventional approach to constructing tiny devices that safely transport and hold these proteins within a cell.

He starts by making nanometer-sized hollow shells of phospholipids that self-assemble. The self-assembled phospholipids are then “polymerized,” or chemically linked, to form the sensors. Since phospholipids are the major component of cell membranes, they are biocompatible. A hundred can be released inside a cell without affecting cellular functions. The shells’ hollow shape allows them to safely hold water-soluble — or even toxic — indicator dyes and enzymes that can be used to ferret out the details of chemistry inside living cells.

In short, chemists can select proteins that interact with specific ions, molecules or groups of molecules, stick them into nanoshell membranes, and send them inside the cell to sniff out specific substances.

“What we’re trying to do at this point is incorporate ion channels as detectors,” Aspinwall said. An ion channel is a molecule that moves a specific kind of ion by opening or closing in response to the presence of that ion or certain other chemicals. When that ion or these chemicals move through the ion channel into the nanoshell, it modifies the ion channel protein. Scientists can detect that change by a variety of techniques.

Aspinwall’s group has monitored oxygen using the new sensor, and his team is also constructing a glucose sensor, which may help in fighting diabetes.

“Anything that interacts with a membrane protein or anything that can be transported by a membrane protein is a potential target,” Aspinwall said. “This opens up an entirely new world of molecules that chemists can look at.”

“What really makes our sensors novel is that, to my knowledge, we are the only group working with a functional, polymerized lipid,” Aspinwall said. “There is no commercially available product like this. It has to be synthesized on this campus.”

The late David O’Brien, who was also a UA chemist, laid the groundwork for this new technology when he began making self-assembing lipid polymers in his laboratory a decade ago. UA chemists working in his lab have created chemically and environmentally stable polymer lipids, which have made Aspinwall’s research possible.

These bio-friendly polymers can be exposed to chemicals and radiation, dehydrated and rehydrated, heated, or stored for long periods of time, yet remain intact.

Aspinwall will discuss this new technology today at the American Chemical Society national meeting in Anaheim, Calif

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…