First Use of a Membrane Bioreactor with Reverse Osmosis in the Pulp and Paper Industry anywhere in the World

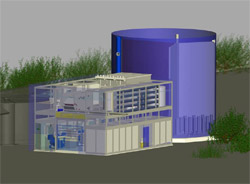

Computer-animated image of the wastewater treatment plant<br>

The Siemens Industry Solutions Division (IS) has received an order from Albert Köhler GmbH & Co. KG in Gengenbach, Germany, to install a membrane bioreactor plant with downstream reverse osmosis for wastewater treatment.

This means the German board producer will be the first company in the world to have such a capability at its disposal. The system will enable almost all the process water to be reused and will reduce the volume of wastewater by some 90 per cent. Not only that: the Siemens solution will reduce the need for process steam and thus cut energy costs. The new wastewater treatment plant is due to be commissioned as soon as the spring of 2008.

Albert Köhler GmbH & Co. KG, based in Gengenbach, Baden-Württemberg, employs 120 people and uses a Fourdrinier machine and two cylinder wrap machines to produce about 40,000 tonnes of high-quality board each year for folders, books and packaging, for the automotive industry, the construction sector and the woodworking industry and for advertising and display products. In order to counter the cost pressure from rising energy costs and water charges while at the same time reducing environmental impact, in June 2007 Albert Köhler GmbH commissioned Siemens to investigate the potential of a wastewater treatment system using a membrane bioreactor (MBR) with integrated partial flow treatment as part of a pilot project.

Following the successful conclusion of the pilot phase, this solution concept will now be implemented for the entire wastewater treatment system at Albert Köhler. For this, the wastewater is first cooled by means of a plate heat-exchanger system downstream of the existing primary treatment stage. The wastewater then passes into the biological clarification plant. This consists of an aerobic stage with three cascades and is operated with an activated sludge concentration of 8-10 g/l. A membrane operating system (MOS) serves as the separating facility. Activated sludge and air are injected here using the MemJet process. The resultant optimized flow to the membranes causes intensive cleaning of the membrane surface in ongoing operation, which helps achieve higher specific throughput rates and longer cleaning intervals. This means that the membranes can also be operated efficiently and economically at high CaCO3 loadings and sludge concentrations – key prerequisites for use in the paper and pulp industry, where polluting loads are high.

The MOS system consists of three parallel lines, which allows fully automatic cleaning of the membranes during operation without causing any changes to the hydraulics. A partial flow treatment stage with reverse osmosis (RO) is installed downstream of the MBR plant. Its purpose is desalination of the wastewater. As a result it is possible to return 90 per cent of all the wastewater to production with no loss of quality in the product. The ultrafiltrated wastewater is piped via an interim tank and a pumping station back to the existing fresh water reservoir. From there, the treated water is distributed through the production system together with the fresh water (supplementary water).

The mechanical engineering and all the plant technology is being produced in a containerized design, accommodated in six container modules. This will enable construction to be completed in only two months. Installation work on site will therefore be reduced to establishing the links between the modules and integrating the activation stage. As well as turnkey delivery of the new wastewater treatment plant, Siemens is also responsible for approval planning, engineering and construction of the plant.

In addition to reducing expenditure on fresh water and wastewater, the Siemens solution will also make a significant contribution to conserving energy. Because the process water can be largely reused, less steam needs to be produced in the power plant. This reduces both fuel costs and CO2 emissions from the plant.

The comprehensive wastewater treatment solution with the key core technologies of a membrane bioreactor with integrated ultrafiltration and downstream reverse osmosis plant constitutes an innovation in the paper industry which has never been implemented before in this form anywhere in the world. The system allows for an optimum combination of economic efficiency and environmental protection. For that very reason the German Federal Environment Agency has recommended its inclusion in the program run by the Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU) to promote investment in demonstration projects designed to reduce environmental impact.

The Siemens Industry Sector (Erlangen, Germany) is the world's leading supplier of production, transportation and building systems. Integrated hardware and software technologies combined with comprehensive industry-specific solutions enable Siemens to enhance the productivity and efficiency of its customers in industry and infrastructure. The Sector comprises six Divisions: Building Technologies, Industry Automation, Industry Solutions, Mobility, Drive Technologies and Osram. In fiscal 2007 (ended September 30), Siemens Industry generated sales of approximately EUR40 billion (pro forma, unconsolidated) with around 209,000 employees worldwide.

With the business activities of Siemens VAI Metal Technologies, (Linz, Austria), Siemens Water Technologies (Warrendale, Pa., U.S.A.), and Industry Technologies, (Erlangen, Germany), the Siemens Industry Solutions Division (Erlangen, Germany) is one of the world's leading solution and service providers for industrial and infrastructure facilities. Using its own products, systems and process technologies, Industry Solutions develops and builds plants for end customers, commissions them and provides support during their entire life cycle.

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…