Functional coatings from the plasma nozzle

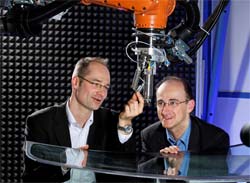

Dr. Jörg Ihde and Dr. Uwe Lommatzsch (from left to right) have developed a new coating process for functional nano-layers, using a plasma nozzle that works at atmospheric pressure. © Dirk Mahler / Fraunhofer<br>

When manufacturing products, the coating technology is a key innovation driver for almost all areas of daily life – for example, for making scratch-proof displays for smart phones or anti-bacterial surfaces in refrigerators. Other coatings protect components from corrosion or aging, for example in a solar cell module or a car engine, without the end user noticing their existence.

In industry today, wet chemical processes or vacuum plasma processes are primarily used for coating applications. Both have drawbacks. Vacuum units are expensive, limited to smaller components and applying a coating takes a relatively long time. Wet chemical processes often involve high resource and energy consumption with the corresponding environmental damage and can also cause difficulties in the handling of material combinations for lightweight construction such as plastics/ metals or aluminum/steel.

“There has to be another way”, thought Dr. Jörg Ihde and Dr. Uwe Lommatzsch from the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Bremen. Together with Plasmatreat GmbH, the IFAM team developed a new kind of plasma coating process that works at ambient pressure, that is to say, in an open atmosphere. “And that poses a major challenge”, explains Jörg Ihde. “Because the pressure is more than 10,000 times higher and the absence of a vacuum reactor, we had to stop unwanted particles from forming and embedding in the coating. That was the key to developing robust and efficient industrial processes using the new plasma system.

One nozzle – various functional coatings

The central element is a plasma nozzle. The nozzle is no bigger than a typical spray can. Yet it contains a highly complex coating system. “In the nozzle, an electrical discharge generates small flashes – a plasma that is expelled from the nozzle in the form of a jet. We systematically feed into the nozzle outlet those materials that are excited and fragmented in the plasma and then deposited out of the plasma jet as a functional nano-layer onto the surface”, explains Uwe Lommatzsch. “We achieve extremely high deposition rates, enabling fast and cost-effective production processes to be realized.”

The use of a nozzle allows the coating to be applied very precisely and only where it is needed, thus conserving resources. “We can control the processes so that the same nozzle can be used to apply coatings with various functionalities, for corrosion protection or for increasing or reducing adhesion, for instance”, adds Jörg Ihde. Only very small amounts of coating material are required and practically all materials and material combinations can be coated. The process offers, in addition to the coating qualities and functionalities, even more benefits: it can be easily integrated into an inline production process, requires little space and is easy to automate, meaning it can be controlled via a robot. Yet another advantage: low investment costs and easy on the environment. The positive characteristics benefit industrial production: depositing an adhesion-promoting coating on a car window edge before gluing it in, to replace environmentally damaging chemicals or as a substitute for thick protective paint on printed circuit boards, which improves heat dissipation and hence prolongs service life. The process is already employed in the automotive industry and the energy sector to provide protection against corrosion and aging.

One of this year‘s Joseph-von-Fraunhofer prizes was awarded to Dr. Jörg Ihde and Dr. Uwe Lommatzsch for their development of a resource-efficient process for the high-rate deposition of functional nano-layers.

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…