Fiber-Laser System for optimized industrial Micro-Material Processing

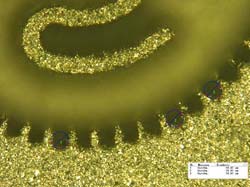

Microscopic image of a workpiece made of V70 hard metal, which can be used a stamp.<br>

Industry has placed a long list of demands on micro-machining laser systems – the laser beam must be easy to focus, nearly non-fluctuating, and beam re-alignment should be minimised. The system must be as compact as possible, placed close to the workpiece, yet not susceptible to rough manufacturing environments.

Up to now, solid-state lasers have been used for metal micro-machining. These systems are usually based on free-beam set-ups, which are easily brought out of alignment. Since the laser systems need water cooling, they are relatively large and difficult to integrate into the production line.

A newly developed, fiber-based picosecond laser system fulfils all the requirements for industrial use. It is the result of a research project PULSAR (PUlsed Laser System with Adaptive Pulse PaRameters). This system is especially flexible and adaptable to different settings because the laser oscillator and amplifier are separated. Depending on the material and the desired process results, the repetition frequency and the average output can be easily adapted to the current process. Thus, quick and up to now unique optimization of the work steps is possible.

A laser diode with a wavelength of 1,03 µm and a pulse length of approximately 40 ps serves as the pulse source. The pulse repetition rate is highly flexible, and can be set between 50 kHz and 40 Mhz. Using a three-step amplifier, the pulse can be amplified from several 10 µW to an average output power of 14 W. At a repetition rate of 1 MHz, a pulse energy of 14 µJ is possible.

The fiber-based, picosecond laser system has an excellent beam quality, and is resistant to difficult production environments, such as dust contamination, temperature fluctuation, or mechanical vibrations. Also, very good results in working aluminum or brass have been achieved. Further, the system is smaller and less expensive than conventional solid-state lasers. There are many fields of applications for this new, high-power laser; among them marking aluminum, or for making stamps of hard metal (V70), for example for stamping coins.

The project PULSAR is subsidized by the BMBF initiative INLAS (Integrated-optical Components for High-power Laser Sources; FKZ: 13N9685). The companies PicoQuant GmbH, InnoLight GmbH, LPKF Laser & Electronics AG, cicor Microelectronics and Alltec GmbH FOBA Laser Marking + Engraving are also involved in the project (see www.ot-inlas.de/pulsar/).

Results of the LZH subproject were presented at the LASE conference/Photonics West 2011 in San Francisco (report number 7914-36) and in the journal Optics Express 19(3), p. 1854 (2011) entitled „All-fiber based amplification of 40 ps pulses from a gain-switched laser diode“.

Contact:

Laser Zentrum Hannover e.V.

Michael Botts

Hollerithallee 8

D-30419 Hannover

Germany

Tel.: +49 511 2788-151

Fax: +49 511 2788-100

E-Mail: m.botts@lzh.de

The Laser Zentrum Hannover e.V. (LZH) carries out research and development in the field of laser technology and is supported by the Ministry of Economic Affairs, Labour and Transport of the State of Lower Saxony (Niedersächsisches Ministerium für Wirtschaft, Arbeit und Verkehr).

Media Contact

More Information:

http://www.lzh.deAll latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…