Revolutionary Microshutter Technology Hurdles Significant Challenges

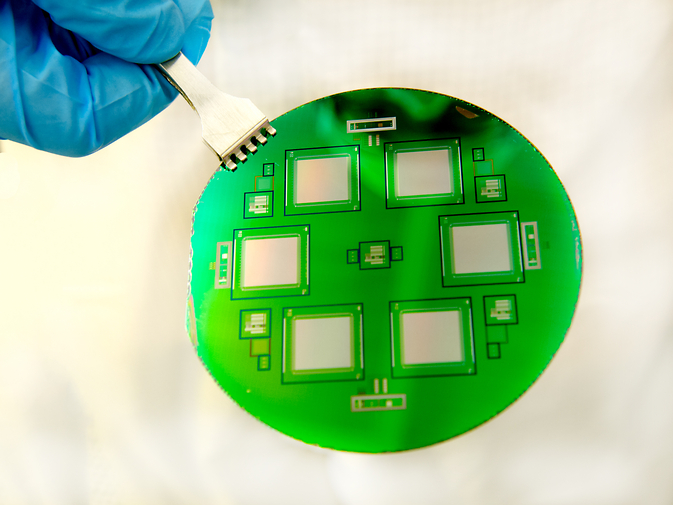

This image shows a close-up view of the next-generation microshutter arrays during the fabrication process. The technology advances an already groundbreaking multi-object observing technique. Image Credit: NASA/Bill Hrybyk

The team, led by Principal Investigator Harvey Moseley, a scientist at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, has demonstrated that electrostatically actuated microshutter arrays — that is, those activated by applying an specific voltage — are as functional as the current technology’s magnetically activated arrays.

This advance makes them a highly attractive capability for potential Explorer-class missions designed to perform multi-object observations.

“We have identified real applications — three scientists want to use our microshutter arrays and the commercial sector has expressed interest,” said Mary Li, a Goddard engineer who is working with Moseley and other team members to fully develop this already groundbreaking observing technology.

“The electrostatic concept has been fully demonstrated and our focus now is on making these devices highly reliable.”

Progress, she said, is in large part due to the fact that the team successfully eliminated all macro-moving parts — in particular, a large magnet — and dramatically lowered the voltage needed to actuate the microshutter array. In addition, the team applied advanced electronic circuitry and manufacturing techniques to assure the microshutter arrays’ dependable operation in orbit, Li added.

The Microshutter Breakthrough

Considered among the most innovative technologies to fly on the Webb telescope, the microshutter assembly is created from micro-electro-mechanical technologies and comprises thousands of tiny shutters, each about the width of a human hair.

Assembled on four postage-size grids or arrays, the 250,000 shutters open or close individually to allow only the light from targeted objects to enter Webb’s Near Infrared Spectrograph (NIRSpec), which will help identify types of stars and gases and measure their distances and motions. Because Webb will observe faint, far-away objects, it will take as long as a week for NIRSpec to gather enough light to obtain good spectra.

NIRSpec’s microshutter array, however, enhances the instrument’s observing efficiencies. It will allow scientists to gather spectral data on 100 objects at a time, vastly increasing the observatory’s productivity. When NASA launches the Webb telescope in 2018, it will represent a first for multi-object spectroscopy.

Quest to Improve Design

Determined to make the microshutter technology more broadly available, Goddard technologists have spent the past four years experimenting with techniques to advance this capability.

One of the first things the team did was eliminate the magnet that sweeps over the shutter arrays to activate them. As with all mechanical parts, the magnet takes up space, adds weight, and is prone to mechanical failure. Perhaps more important, the magnet cannot be easily scaled up in size without creating significant fabrication challenges. As a result, the instrument’s field of view — that is, the area that is observable through an instrument — is limited in size. This greatly impedes next-generation space observatories that will require larger fields of view.

Magnetic activation also takes longer. With the Webb telescope, the magnet must first sweep over the array to open all the shutters before voltages are selectively applied to open or close specific shutters.

Achieving the Voltage Sweet Spot and Other Milestones

To accommodate the needs of future observatories, the team replaced the magnet with electrostatic actuation. By applying an alternating-current voltage to electrodes placed on the frontside of the microshutters, the shutters swing open. To latch the desired shutters, a direct current voltage is applied to electrodes on the backside. In other words, only the needed shutters are opened; the rest remain closed. “This reduction in cycles should allow us to extend the lifetime of the microshutter arrays 100 times or more,” Li explained.

And because the magnet no longer dictates the size of the array, its elimination will allow scientists to assemble much larger arrays for instruments whose fields of view are 50 times larger than Webb’s NIRSpec, she said.

Just as significant is the voltage needed to actuate the arrays. When the effort first began four years ago, the team only could open and close the shutters with 1,000 volts. By 2011, the team had slashed that number to 80 volts — a level that still could exceed instrument voltage specifications. By last year, the team had achieved a major milestone by activating the shutters with just 30 volts — a voltage sweet spot, Li said.

“But we also did something else,” she added.

Through experimentation, the team used atomic layer deposition, a state-of-the-art fabrication technology, to fully insulate the tiny space between the electrodes to eliminate potential electrical crosstalk that could interfere with the arrays’ operation.

The team also applied a very thin anti-stiction coating to prevent the shutters from sticking when opened. Before applying the coating, a 3,000-cycle laboratory test indicated that a third of the shutters stuck. After coating them, the team ran a 27,000-cycle test and not a single shutter adhered to the sides, Li said.

Success Breeds Success; More Work Ahead

As a result of the progress, Li said three astrophysicists now are interested in applying the technology to their own mission concepts, which include observing nearby star-forming regions in the ultraviolet, studying the origins of astronomical objects to better understand the cosmic order, and understanding how galaxies, stars, and black holes evolve. In fact, one of those scientists is so committed to advancing the microshutter array that he plans to demonstrate it during a sounding-rocket mission next year, Li said.

Although spectroscopy — the study of the absorption and emission of light by matter — is the obvious beneficiary of the technology’s advance, Li said it also is applicable to lidar instruments that measure distance by illuminating a target with a laser and analyzing the reflected light. A major automotive company also has expressed interested in the technology, she added.

However, before others can use the new and improved microshutter technology, Li said the team must develop an assembly and packaging to house multiple arrays. “If you want to use the microshutter array on a large telescope, we need to make a larger field of view. To make this happen, we need to take multiple arrays and stitch them together,” Li said.

Currently, the technology relies on a large computerized switch box — a heavy device unsuitable for spaceflight missions. The team plans to incorporate an integrated circuit, or silicon chip, that drives the switching functions. Placed next to the shutters, the circuit would take up only a fraction of the space. The team currently is identifying circuits from different vendors and plans to begin testing shortly.

“In just four years, we have made great progress. A major private company has expressed interest in our technology, to say nothing of the three potential astrophysics missions,” Li said. “Given our progress, I am confident that we can make this technology more readily accessible to the optics community.”

Related News

› More technology news

› More about Advanced Technology Large-Aperture Space Telescope (ATLAST)

Lori Keesey

NASA Goddard Space Flight Center, Greenbelt, Maryland

Media Contact

All latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…