Researchers uncover secrets behind nanotube formation

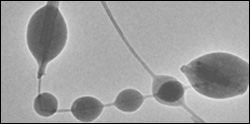

Glassy drops of carbon coat the fibers that house nanotubes after their synthesis with a carbon arc.

Nanotubes are ubiquitous in the world of science. Although several methods for making them exist, little is known about how these techniques physically produce the hollow fibers of carbon molecules known as nanotubes, that is until now. A multinational team of scientists has discovered that multi-walled carbon nanotubes made by the pure carbon arc method are, in fact, carbon crystals that form inside drops of glass-coated liquid carbon. The research appears in the 11 February 2005, issue of the journal Science, published by the AAAS, the science society, the world’s largest general scientific organization.

One way to make nanotubes involves using a carbon arc to heat graphite to about 5,000 C. An electrical current is passed through the graphite in a chamber filled with helium gas. The result is a sooty deposit on one of the electrodes that contains columns filled with nanotubes. “We were doing research on the electrical transport properties of carbon nanotubes when we noticed that the nanotubes had these little beads that looked like liquid drops on them, said lead author Walt A. de Heer, physics professor at the Georgia Institute of Technology.

Much like archeologists studying artifacts to decipher what happened in centuries past, the research team began with the photos of the liquid-like beads coating the nanotube fibers and worked their way back to try to find out how they got there. “Just by looking at them we realized that this has something to do with liquid,” said de Heer. “So we asked the question, if the beads were once liquid carbon and the nanotubes they are attached to are also carbon, why didn’t the liquid carbon dissolve the nanotube? The answer is that the liquid must have been a glass at a lower temperature than the nanotube.”

It is well known that glass is made by rapidly cooling a liquid. The fast rate of cooling doesn’t allow the molecules time to align themselves in the orderly arrangement of crystals and they remain in the disordered grouping of the liquid.

The research team saw that the beads had the disordered grouping characteristic of glass, while the nanotubes they surrounded had an orderly crystalline pattern. This lead them to conclude that the carbon arc must have melted the graphite into drops of liquid carbon, which had cooled at a much faster rate on the outside, giving it a glassy appearance.

Since the nanotubes in the interior had a crystalline structure, the team reasoned that the liquid carbon on the inside of the drops had cooled so slowly it became a supercooled liquid, which is a liquid below the temperature which normally turns it into a solid. As the temperature of any supercooled liquid drops to a certain critical temperature, it begins to crystallize. Which in this case, researchers reasoned, resulted in the orderly molecular structure of the nanotubes.

As the nanotubes continue to crystalize they lengthen – poking through the glass layer – causing the glass to bead on the tubes much like water beads on pine needles. This final portrait of the beads on nanotube fibers is the photo that began the research team’s initial questions. “Before we began this work, we had spent a lot of time investigating these fibers, because they had special significance for our work. Most people don’t look at the fibers. They open them up to get the nanotubes inside, but the balls are on the surface.” said de Heer. “It took us having to see them several times – actually they were quite annoying – but then we realized that they may have some significance by themselves We hope our results will open up the whole question of nanotube formation again.”

The research team consists of de Heer and Zhimin Song from the Georgia Institute of Technology, Daniel Ugarte from Universidade Estadual de Campinas and Laboratorio Nacional de Luz Sincrotron in Brazil, Jefferson Bettini also from Laboratorio Nacional de Luz Sincrotron, Philippe Poncharal from Universite Montpellier in France, Claire Berger from the Georgia Institute of Technology and the Laboratoire d’Études des Propriétés Électroniques des Solides in France and Joseph Ghezo from the University of Illinois at Urbana-Champaign.

Media Contact

All latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…