Late Afternoon at Taruntius

A small area of the lunar surface, on the rim of the 56-km crater Taruntius <br>© European Southern Observatory

Amazingly Sharp VLT Image of Lunar Landscape

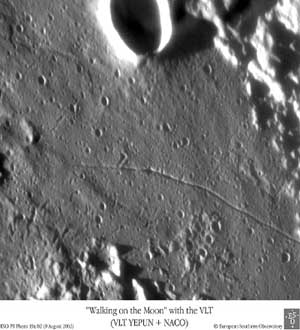

Thirty-three years after the first manned landing on the Moon, the ESO Very Large Telescope (VLT) has obtained what may be the sharpest image of the lunar surface ever recorded from the ground. It was made with the NAOS-CONICA (NACO) adaptive optics camera mounted on the ESO VLT 8.2-m YEPUN telescope at the Paranal Observatory.

The photo (ESO PR Photo 19a/02) shows an area about 700 km from the Apollo XI landing site. The location is in the Eastern hemisphere, just North of the lunar equator, and right between two of the major “seas”, Mare Tranquillitatis (Sea of Tranquillity) and Mare Foecunditatis (Sea of Fertility).

The field-of-view measures about 60 x 45 km2 (taking into account the foreshortening because of the viewing angle), with part of a sunlit, 10-km wide crater named Cameron [1] surrounded by a comparatively level terrain, bordered by some hills and, not least, with an incredible number of smaller craters.

The site of this NACO photo is situated at the rim of an older, rather eroded 56-km crater, Taruntius [1]. A small part of the multiple walls of that crater are seen in the upper right corner and also to the left of the bottom centre of PR Photo 19a/02. The centre of Taruntius is near the lower right corner of the photo. The rather flat terrain to the left in the photo corresponds to an “opening” in the crater walls.

At the time of the exposure, the Sun was approximately 7deg above the Western horizon to the left [2], and the shadows are therefore quite prominent, approx. 8 times longer than the elevation of the corresponding peaks and hills.

The nominal image sharpness is 0.07 arcsec, or about 130 metres on the lunar surface (in the N-S direction). Elevation differences of a few tens of metres only are therefore visible by the shadows they cast. The VLT image represents what an astronaut (with normal eye acuity of 1 arcmin) would see from 400 km above the surface.

Testing the NAOS-CONICA instrument

This splendid VLT image is a by-product of the ongoing, thorough testing of the NAOS-CONICA (NACO) Adaptive Optics facility, recently installed at the 8.2-m YEPUN telescope, the fourth unit of the Very Large Telescope (VLT) at the ESO Paranal Observatory. This major astronomical instrument has already delivered other impressive views of the Universe, cf. ESO PR 25/01 and ESO PR Photos 04a-c/02.

Normally, NACO functions by “locking” on a point-like guide star, correcting the image smearing caused in the turbulent terrestrial atmophere by measuring the deformation of the recorded image of that star.

However, in the morning of April 30, 2002, shortly before sunrise, the astronomers and engineers working with NACO decided to do a test of wavefront sensing on an extended celestial object. For this, the giant telescope was turned towards the Moon, at that moment seen in the southern constellation of Ophiuchus, high above the western horizon at Paranal [2].

Guiding the advanced instrument on a sunlit lunar peak in the area between Mare Tranquillitatis and Mare Foecunditatis, a short exposure (0.22 seconds) was made through a narrow-band near-infrared filter (at wavelength 2.3 micron), with the adaptive optics (AO) activated in closed-loop mode. The telescope was set to track on that lunar mountain and the flexible AO mirror in NACO superbly “refocussed” the 25 x 25 arcsec2 field-of-view.

Although the atmosphere above Paranal was rather turbulent that morning – the nominal seeing was measured as 1.5 arcsec – and despite the use of an extended feature for the guiding, the NACO adaptive optics compensation achieved nearly theoretical image sharpness, about 0.068 arcsec for this waveband.

Images of other areas on the lunar surface may be attempted in the future with the VLT and NACO.

Notes

[1]: The lunar crater Taruntius (lunar co-ordinates: 5.6deg N; 46.5deg E) was named in 1935 by the International Astronomical Union (IAU) after the Roman philosopher Lucius Firmanus Taruntius (? – 86 B.C.). It measures about 56 km across. The 10-km crater Cameron (6.2deg N; 45.9deg E) was named by the IAU in 1972 after the American astronomer Robert Curry Cameron (1925 – 1972). Names of surface features on planets and their natural satellites, including the Earth`s Moon, are allocated by the “IAU Working Group for Planetary System Nomenclature” and published on the web in the “Gazetteer of Planetary Nomenclature”.

[2]: The NACO image was exposed on April 30, 2002, at 09:42 hrs UT. The geometrical circumstances of this observation were the following: the Moon was located at (Azimuth Az = 266deg; Elevation h = +62deg) in the sky above the VLT at the Paranal Observatory; the Earth (Paranal) was located at (Az = 263deg; h = +50deg) and the Sun at (Az = 268deg; h = +7deg) in the lunar sky above the Cameron crater. The distance from Paranal to the Moon was about 370,000 km.

Media Contact

More Information:

http://www.eso.org/outreach/press-rel/pr-2002/phot-19-02.htmlAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Simplified diagnosis of rare eye diseases

Uveitis experts provide an overview of an underestimated imaging technique. Uveitis is a rare inflammatory eye disease. Posterior and panuveitis in particular are associated with a poor prognosis and a…

Targeted use of enfortumab vedotin for the treatment of advanced urothelial carcinoma

New study identifies NECTIN4 amplification as a promising biomarker – Under the leadership of PD Dr. Niklas Klümper, Assistant Physician at the Department of Urology at the University Hospital Bonn…

A novel universal light-based technique

…to control valley polarization in bulk materials. An international team of researchers reports in Nature a new method that achieves valley polarization in centrosymmetric bulk materials in a non-material-specific way…