Wearable Solar Cells

Your tablet on your jacket sleeve, your smartphone in your watch—conventional batteries are not practicable for ever-lighter wearable electronic devices. A possible alternative is solar cells in the form of a textile that can simple be integrated into clothing. In the journal Angewandte Chemie Chinese researchers have now introduced novel, efficient solar cells based on stable, flexible textile electrodes that can be integrated into fabrics.

Various types of threadlike solar cells that can be woven into textiles have previously been produced by twisting two electrically conducting fibers together as electrodes. Practical application of these has been hampered by the fact that it is difficult to make long, efficient, thread-shaped electrodes.

The wire-shaped cells are limited to lengths of a few millimeters. It has also been difficult to connect a larger number of crossed wire-shaped solar cells that have been woven into electronic textiles.

A team from Fudan University and Tongii University in Shanghai has now developed an alternative approach for the production of flexible solar cells that can be integrated into fabrics. Their method is based on textile electrodes that are stacked into layers.

Solar cells need a working electrode that captures light, as well as a counter electrode and an electrolyte. Researchers led by Huisheng Peng produced their working electrode by weaving titanium wires with a diameter of 130 µm into a fabric. They then used an electrochemical process to grow a layer of parallel titanium dioxide nanotubes perpendicular to the wires.

In a final step, a special dye was introduced into the titanium dioxide nanotubes. For the counter electrode, the researchers produced layers of highly parallel carbon nanotubes that were then twisted into fine threads with a high degree of mechanical strength, which were in turn woven into a textile.

One layer each of working electrode and counter electrode were stacked on top of each other and the double layer was soaked with a liquid electrolyte and sealed or equipped with a solid electrolyte.

When the dye molecules are excited by light, they to release electrons into the conducting band of the titanium dioxide. These charges are carried away through the titanium wires and through an attached external circuit to the counter electrode. The electrolyte takes up electrons from the counter electrode by means of a redox reaction, transferring them back to the ionized dye molecules.

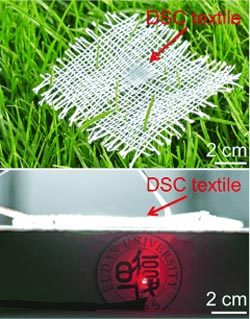

The stacked textile electrodes also work well when they are bent, which allows the textile solar cells to be easily integrated into knit fabrics or other flexible structures. By using several small textile solar cells, the researchers were able to power an LED.

About the Author

Dr. Huisheng Peng is professor in the Department of Macromolecular Science at Fudan University, and has focused on the development of wearable energy devices. He has received over twenty national and international honors and awards including the Chinese Young Scientist Award and Chinese Chemical Society Prize for Young Scientists.

Author: Huisheng Peng, Fudan University, Shanghai (China), http://www.polymer.fudan.edu.cn/polymer/research/Penghs/member_en.htm

Title: Wearable Solar Cells by Stacking Textile Electrodes

Angewandte Chemie International Edition, Permalink to the article: http://dx.doi.org/10.1002/anie.201402561

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…