Tiny self-assembling cubes could carry medicine, cell therapy

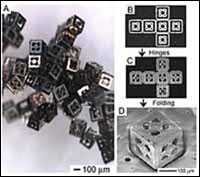

(A) Optical image showing a collection of biocontainers. (B-D) Optical and Scanning electron microscopy images at different stages of the fabrication process: (B) the 2D precursor with electrodeposited surfaces, (C) the precursor with surfaces and hinges, and (D) the self-assembled biocontainer.

Porous metallic boxes can easily be tracked via MRI

Johns Hopkins researchers have devised a self-assembling cube-shaped perforated container, no larger than a dust speck, that could serve as a delivery system for medications and cell therapy.

The relatively inexpensive microcontainers can be mass-produced through a process that mixes electronic chip-making techniques with basic chemistry. Because of their metallic nature, the cubic container’s location in the body could easily be tracked by magnetic resonance imaging.

The method of making these self-assembling containers and the results of successful lab tests involving the cubes were reported in a paper published in the December 2005 issue of the journal Biomedical Microdevices. In the tests, the hollow cubes housed and then dispensed microbeads and live cells commonly used in medical treatment.

“Our group has developed a new process for fabricating three-dimensional micropatterned containers for cell encapsulation and drug delivery,” said David H. Gracias, who led the lab team. “We’re talking about an entirely new encapsulation and delivery device that could lead to a new generation of ’smart pills.’ The long-term goal is to be able to implant a collection of these therapeutic containers directly at the site or an injury or an illness.”

Gracias is an assistant professor in the Department of Biomolecular and Chemical Engineering in the Whiting School of Engineering at Johns Hopkins. He focuses on building micro and nanosystems with medical applications. He believes the microcontainers developed in his lab could someday incorporate electronic components that would allow the cubes to act as biosensors within the body or to release medication on demand in response to a remote-controlled radio frequency signal.

To make the self-assembling containers, Gracias and his colleagues begin with some of the same techniques used to make microelectronic circuits: thin film deposition, photolithography and electrodeposition. These methods produce a flat pattern of six squares, in a shape resembling a cross. Each square, made of copper or nickel, has small openings etched into it, so that it eventually will allow medicine or therapeutic cells to pass through.

The researchers use metallic solder to form hinges along the edges between adjoining squares. When the flat shapes are heated briefly in a lab solution, the metallic hinges melt. High surface tension in the liquified solder pulls each pair of adjoining squares together like a swinging door. When the process is completed, they form a perforated cube. When the solution is cooled, the solder hardens again, and the containers remain in their box-like shape.

“To make sure it folds itself exactly into a cube, we have to engineer the hinges very precisely,” Gracias said. “The self-assembly technique allows us to make a large number of these microcontainers at the same time and at a relatively low cost.”

The tiny cubes are coated with a very thin layer of gold, so that they are unlikely to pose toxicity problems within the body. The microcontainers have not yet been implanted in humans or animals, but the researchers have conducted lab tests to demonstrate how they might work in medical applications.

Gracias and his colleagues used micropipettes to insert into the cubes a suspension containing microbeads that are commonly used in cell therapy. The lab team showed that these beads could be released from the cubes through agitation. The researchers also inserted human cells, similar to the type used in medical therapy, into the cubes. A positive stain test showed that these cells remained alive in the microcontainers and could easily be released.

At the Johns Hopkins School of Medicine’s In Vivo Cellular and Molecular Imaging Center, researcher Barjor Gimi and colleagues then used MRI technology to locate and track the metallic cubes as they moved through a sealed microscopic s-shaped fluid channel. This demonstrated that physicians will be able to use non-invasive technology to see where the therapeutic containers go within the body. Some of the cubes (those made mostly of nickel) are magnetic, and the researchers believe it should be possible to guide them directly to the site of an illness or injury.

The researchers are now refining the microdevices so that they have nanoporous surfaces. Gimi, whose research focuses on magnetic resonance microimaging of cell function, envisions the use of nanoporous devices for cell encapsulation in hormonal therapy. He also envisions biosensors mounted on these devices for non-invasive signal detection.

“We believe these self-assembling microcontainers have great potential as a new tool for medical diagnostics and treatment,” Gracias said.

Lead author on the Biomedical Microdevices paper was Gimi, a post-doctoral fellow in the Russell H. Morgan Department of Radiology and Radiological Science in the Johns Hopkins School of Medicine. Gracias served as senior author. Co-authors were Timothy Leong, a doctoral student in the Johns Hopkins Department of Biomolecular and Chemical Engineering; Zhiyong Gu, a postdoctoral fellow in the Department of Biomolecular and Chemical Engineering; Michael Yang, an undergraduate majoring in biomedical engineering; Dmitri Artemov, an associate professor in the Department of Radiology; and Zaver M. Bhujwalla, a professor in the Department of Radiology and director of the In Vivo Cellular and Molecular Imaging Center.

Media Contact

More Information:

http://www.jhu.eduAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…