Faster, cheaper tests for sickle cell

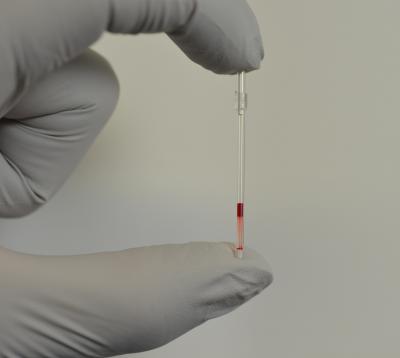

This is a capillary tube showing a positive test for sickle cell disease. The system works by using polymers which self-assemble into layers which can separate red blood cells according to their density. The more dense cells infected with sickle cell disease fall to the bottom of the tube. Credit: AJ Kumar

Within minutes after birth, every child in the U.S. undergoes a battery of tests designed to diagnose a host of conditions, including sickle cell disease. Thousands of children born in the developing world, however, aren't so lucky, meaning many suffer and die from the disease each year.

A.J. Kumar hopes to put a halt to at least some of those deaths.

A Post-Doctoral Fellow in Chemistry and Chemical Biology working in the lab of George Whitesides, the Woodford L. and Ann A. Flowers University Professor, Kumar and colleagues, including other co-authors, have developed a new test for sickle cell disease that provides results in just 12 minutes and costs as little as 50 cents – far faster and cheaper than other tests. The test is described in a paper published this week in the Proceedings of the National Academy of Sciences.

“The tests we have today work great, they have a very high sensitivity,” Kumar said. “But the equipment needed to run them costs in the tens of thousands of dollars, and they take hours to run. That's not amenable to rural clinics, or even some cities where the medical infrastructure isn't up to the standards we see in the U.S. That's where having a rapid, low-cost test becomes important and this paper shows such a test can potentially work.”

When run against more than 50 clinical samples – 26 positive and 26 negative – the new test showed good sensitivity and specificity for the disease, Kumar said, so the early evidence is promising, but additional testing will be needed to determine whether the test is truly accurate enough to use in the field.

The test designed by Kumar is deceptively simple, and works by connecting two ideas scientists have understood for decades.

The first is the notion that blood cells affected by the disease are denser than normal cells, and the second is that many polymers, when mixed in water, automatically separate into layers ordered by density.

Conventional methods to separate cells by density relied on layering liquids with different density by hand. The insight, arrived at by Charles Mace (now at Tufts) and Kumar, was that the self-forming layers could be used to separate cells, such as red blood cells, by density.

“When you mix the polymers with water, they separate just like oil and water,” he said. “Even if you mix it up, it will still come back to those layers.”

It wasn't until a chance meeting with Dr. Thomas Stossel, however, that Kumar believed the technology might have a real impact on sickle cell disease.

“Initially, we started off working on malaria, because we thought when parasites invaded the cells, it would change their density,” he said. “But when I met Tom Stossel on a panel at the Harvard Medical School, he said, 'You need to work on sickle cell.' He's a hematologist by training and has been working with a non-profit in Zambia for the past decade, so he's seen the need and the lack of a diagnostic tool.”

When Kumar and colleagues ran tests with infected blood, their results were unmistakable. While healthy red blood cells settled in the tubes at specific levels, the dense cells from blood infected with sickle cell settled in a band significantly lower. The band of red cells could clearly be seen by eye.

Just showing that the test worked, however, wasn't enough.

“We wanted to make the test as simple as possible,” Kumar explained. “The idea was to make it something you could run from just a finger prick. Because these gradients assemble on their own, that meant we could make them in whatever volume we wanted, even a small capillary tube.”

The design the team eventually settled on is barely larger than a toothpick. In the field, Kumar said, running the test is as simple as uncapping the tube, pricking a patient's finger and allowing the blood to wick into the tube.

While further study is needed to determine how accurate and effective the test may be, Kumar said stopping even a few sickle-cell-related deaths would represent a victory.

“The best way to state it is in terms of the actual problem,” he said. “About 300,000 children are born every year with sickle cell disease, and the vast majority – about 80 to 90 percent – are in either Africa or India, where for the most part, they aren't going to get access to the current screening tests.

“There were studies recently that showed in sub-Saharan Africa, between 50 and 90 percent of the children born with sickle cell disease die before the age of 5,” he continued. “Whereas in the U.S. people don't die from this disease as children, they can still live a full life. So my hope is that if this test is effective, it can make some small dent in those numbers.”

Media Contact

More Information:

http://www.harvard.edu/All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…