Explosive Nanotechnology

<br>

Whether they are rocket propellants or fireworks, all explosives contain a fuel and an oxidizing agent. Sometimes both are in the same molecule, like in TNT; sometimes the explosive is a mixture, like Thermite.

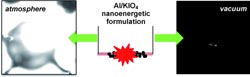

In mixtures, the smaller the particles, the higher the explosive force. American scientists have reported in the journal Angewandte Chemie a new aerosol spray drying method for the generation of periodate nanoparticles that can be used in the formulation of highly reactive explosives.

Energetic mixtures usually have a higher energy density than explosive materials with both components in a single molecule. However, mixtures generally release the energy more slowly because the reaction partners have to find each other.

Nanoenergetics researchers are attempting to achieve faster and more intensive mixing of the fuel and oxidizing agents by drastically reducing the scale of the distances involved. In most nanoenergetic formulations, nanoaluminum (aluminum nanoparticles) is used as the fuel and metal oxides as the oxidizing agents.

Highly oxidizing compounds with high oxygen content, such as perchlorate are an alternative, but cannot be stored as long, partly because they are very hygroscopic. Perchlorates can also cause health problems and environmental damage. Periodates are possible substitutes. They are minimally toxic and don’t absorb water. However, the production of nanoparticles of periodate salts has proven very difficult.

A team led by Michael R. Zachariah at the University of Maryland has now overcome this problem. Their secret is a simple but versatile aerosol spray drying process. An aqueous solution is continuously atomized to form microdroplets, which give off water as they dry, forming nanoscopic grains of salt.

In formulations with nanoaluminum as fuel, this new nanoperiodate demonstrated superior reactivity. “Our formulations resulted in the highest gas pressure pulses described to date for nanoenergetic materials,” reports Zachariah.

By using special electron microscopic and mass spectrometric techniques in which the samples can be heated extremely fast, the researchers explored the reaction mechanisms involved.

They discovered that the release of gas-phase oxygen is critical for the ignition and combustion of the periodate formulations. The decomposition of potassium periodate (KIO4) takes place in two steps. First oxygen splits off.

The resulting KIO3 then further decomposes to potassium iodide (KI) and oxygen. “Different from most metal oxide decompositions, the first step of periodate decomposition is exothermic, releasing heat,” explains Zachariah. “This is presumably the reason for the low ignition temperature.”

About the Author

Dr. Michael R. Zachariah is a Professor of Chemical Engineering and Chemistry at the University of Maryland. His expertise is in the area of nanoparticle synthesis and metrology, and the high temperature materials chemistry of nanomaterials including those related to energetic.

Author: Michael Zachariah, University of Maryland, College Park (USA), http://www.chem.umd.edu/michael-zachariah/

Title: Super-reactive Nanoenergetic Gas Generators Based on Periodate Salts

Angewandte Chemie International Edition, Permalink to the article: http://dx.doi.org/10.1002/anie.201303545

Media Contact

More Information:

http://pressroom.angewandte.orgAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…