More-Efficient Production of Large-Scale Batteries

<br>

The future will see a growing need for large-scale lithium-ion batteries, not only to store energy but also, and in particular, to power electric vehicles. Automation technology from Siemens will enable battery producers to reduce their manufacturing costs and boost productivity.

In devising such solutions, Siemens has combined its expertise in the production of energy-storage devices and its technological know-how in the field of automation and control systems. Together with the Karlsruhe Institute of Technology (KIT), Siemens now plans to further enhance this technology for battery manufacturers.

Wind and solar power plants already generate large amounts of electricity. The need to supply this energy as and when required will boost demand for energy-storage devices. These in turn must become cheaper to produce – especially lithium-ion batteries – while offering high quality.

The process used to manufacture such batteries, which can be as large as a shipping container, is still in its infancy. The chemical processes in the battery cells are complex and highly sensitive. The foil coating of the electrodes, for example, must not deviate from regulation thickness by more than one micrometer across the entire coated surface. What's more, this condition must be fulfilled even though manufacturing is carried out at a speed of several tens of meters per minute.

Siemens has great expertise in the areas of automation and drive technology, production-planning, and design software. All of these areas play a role in efforts aimed at making the production of large-scale lithium-ion batteries efficient. For example, Siemens software creates digital models of planned production facilities. As a result, it is possible to determine the required size of the plant, calculate the maximum potential throughput, and optimize efficiency. These simulation results can then be applied without further modification to real live plants. Simlarly, quality-control systems can be directly integrated within fully automated production machinery.

In a recently signed cooperation agreement, KIT and Siemens agreed to collaborate on an overarching concept for an integrated production-control and monitoring system for the entire production machinery of a battery plant. The aim is to develop a primary control system that will provide online monitoring of all processes via a central computer. Sometime this year, the system is to be installed in the first production facility for lithium-ion cells of the KIT, where it will highlight the benefits in terms of product quality and reduced costs.

Media Contact

More Information:

http://www.siemens.com/innovationnewsAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Economies take off with new airports

A global study by an SUTD researcher in collaboration with scientists from Japan explores the economic benefits of airport investment in emerging economies using nighttime satellite imagery. Be it for…

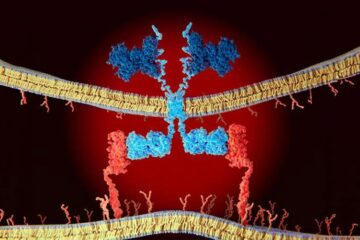

CAR T–cell immunotherapy targets

Pan-cancer analysis uncovers a new class of promising CAR T–cell immunotherapy targets. Scientists at St. Jude Children’s Research Hospital found 156 potential CAR targets across the brain and solid tumors,…

Stony coral tissue loss disease

… is shifting the ecological balance of Caribbean reefs. The outbreak of a deadly disease called stony coral tissue loss disease is destroying susceptible species of coral in the Caribbean…