26.1 % record efficiency for p-type crystalline Si solar cells

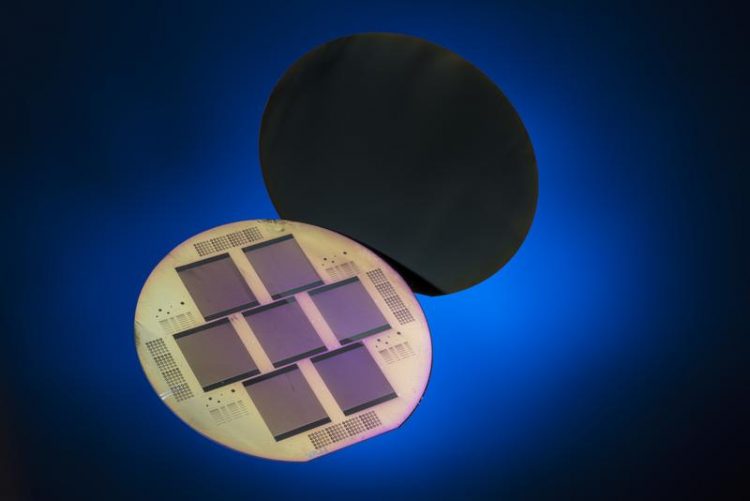

Monocrystalline silicon solar cell with POLO-contacts for both polarities on the solar cell rear side. In the foreground the rear side of seven solar cells processed on one wafer can be seen. ISFH

The Institute for Solar Energy Research Hamelin (ISFH) and the Leibniz Universität Hannover demonstrated the fabrication of a crystalline silicon solar cell on p-type wafer material with an independently confirmed energy conversion efficiency of (26.10 +/- 0.31) % under one sun. This is a world record for p-type Si material as well as a European record for crystalline Si.

The other parameters of the current-voltage curve of the record cell are: Open circuit voltage (726.6 +/- 1.8) mV, short circuit current density (42.62 +/- 0.4) mA/cm2, fill factor (84.28 +/- 0.59) %, designated area 4 cm2. The measurement was performed at the ISO 17025-accredited Calibration and Test Center, ISFH-CalTeC.

Today about 90% of the photovoltaic world market is being served with p-type silicon material. However, efficiencies above 25% were so far only demonstrated on n-type silicon and in combination with either boron diffusions or amorphous silicon hetero-junctions.

“Our result demonstrates that neither n-type silicon nor boron-diffusions, nor amorphous silicon are a must for ultra-high efficiencies. There are also other attractive pathways to highest efficiencies with silicon at potentially low costs!”, states Prof. Rolf Brendel, director of ISFH.

The record cell uses a passivating electron-selective n+-type polysilicon on oxide (POLO) junction at the minus contact of the cell and a hole-selective p+-type POLO junction at the plus contact. It is the high selectivity of theses junctions that allow such high efficiencies. These junctions are applied in an interdigitated pattern on the rear side.

This minimizes the parasitic absorption in the poly-Si and avoids shading by front side metallization. n+-type and p+-type poly-Si are separated from each other by an intrinsic poly-Si region. The doped regions are structured using lab-type processes. However, the opening of the dielectric rear-side reflector is already done by an industrially feasible local laser ablation.

The final objective is to integrate POLO junctions into the current mainstream technology with a clear advantage in efficiency. “Replacing photolithography by laser contact opening is a first important step towards industrialization as it enables screen-printing-based metallization”, states Prof. Robby Peibst, the leader of the workgroup.

ISFH gratefully acknowledges the contributions of the project partner Centrotherm who deposited the poly-Si layer in a LPCVD reactor. The partner Wacker contributed with knowledge of high-temperature processing of Si wafers.

The research at ISFH received financial support from the German Federal Ministry for Economic Affairs and Energy (BMWi) as well as from the State of Lower Saxony.

Media Contact

More Information:

http://www.isfh.de/All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Why getting in touch with our ‘gerbil brain’ could help machines listen better

Macquarie University researchers have debunked a 75-year-old theory about how humans determine where sounds are coming from, and it could unlock the secret to creating a next generation of more…

Attosecond core-level spectroscopy reveals real-time molecular dynamics

Chemical reactions are complex mechanisms. Many different dynamical processes are involved, affecting both the electrons and the nucleus of the present atoms. Very often the strongly coupled electron and nuclear…

Free-forming organelles help plants adapt to climate change

Scientists uncover how plants “see” shades of light, temperature. Plants’ ability to sense light and temperature, and their ability to adapt to climate change, hinges on free-forming structures in their…