Stress relief caused Giant’s Causeway

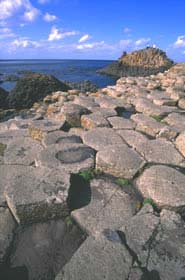

The Giant’s Causeway. <br>© Allan Davies / LGPL <br>

Ireland’s huge hexagonal columns are a natural consequence of lava cooling.

The Giant’s Causeway is not the work of men or monsters, but a natural consequence of how lava cools and solidifies, new computer simulations suggest.

The causeway is a field of roughly hexagonal basalt columns up to 40 feet high on the shores of County Antrim in Northern Ireland. It arose when a flow of volcanic rock split into hexagonal columns to relieve stress, according to Eduardo Jagla of the Centro Atómico Bariloche in Argentina and Alberto Rojo of the University of Michigan in Ann Arbor1.

Viscous lava shrinks as it cools, so rock in a solidifying layer is pulled in all directions at once, the researchers explain. This sets up stresses like those that make paint crack or wrinkle. As this stress increases, cracks appear.

As the causeway’s 40,000 pillars formed, cracks in the solid layer above would have propagated down into the solidifying layer below, like a stack of paint layers drying one after another. These cracks would have been deflected along the way onto new courses that provided the greatest stress relief.

Cracks that form a hexagonal network reduce energy more effectively than randomly orientated cracks, say Jagla and Rojo.

If this idea is correct, the causeway’s hexagonal columns were created by a much more random vertical-cracking structure, which once stood over the columns but has since been eroded by wind, rain and sea. There is geological evidence that the causeway we see today is merely a part of an original solidified lava field.

They might be giants

When the Giant’s Causeway was first reported to the Royal Society in London in 1693, some wondered whether men had created the step-like stone columns with picks and chisels. Local legend attributes them to the Irish giant Finn McCool, said to have wanted to walk to Scotland without wetting his feet. The more prosaic lava-flow explanation was put forward in 1771.

The columns form a natural stairway from a cliff into the sea. All have between four and eight sides, but most are roughly hexagonal. This geometric regularity has perplexed scientists for centuries.

Jagla and Rojo support their idea with computer simulations of fracture patterns in a layer of particles joined by springs, which mimic the mutually attractive atoms in the rock. The researchers simulate shrinking and cracking in a series of particle layers, using the final cracking pattern in one layer as the starting point for the cracking of the layer below.

They find that the pattern evolves from one that has many randomly distributed cracks to one in which the fractures define large polygons, most of which are six-sided.

What’s more, the model correctly predicts the proportions of columns with different numbers of sides and the average cross-sectional areas of these columns.

References

- Jagla, E. A., Rojo, A. G. Sequential fragmentation: the origin of columnar quasihexagonal patterns. Physical Review E, 65, 026203, (2002).

Media Contact

More Information:

http://www.nature.com/nsu/020121/020121-15.htmlAll latest news from the category: Earth Sciences

Earth Sciences (also referred to as Geosciences), which deals with basic issues surrounding our planet, plays a vital role in the area of energy and raw materials supply.

Earth Sciences comprises subjects such as geology, geography, geological informatics, paleontology, mineralogy, petrography, crystallography, geophysics, geodesy, glaciology, cartography, photogrammetry, meteorology and seismology, early-warning systems, earthquake research and polar research.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…