Sensor skin of DuPont™ Hytrel® contributes to pedestrian safety

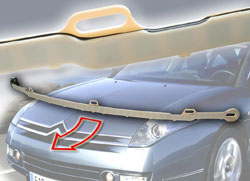

Photo: DuPont <br>Made by Magna Electronics Europe, a sensor strip helps to reduce the risk of pedestrian injuries resulting from a frontal collision with a car. The strip, between 1,1 and 1,4 metres long, is made in sandwich construction. For the strip’s outer skin Magna chose DuPont™ Hytrel® 5556 thermoplastic polyester elastomer.

The sensor strip is made in sandwich construction. Developed by systems supplier Magna Electronics Europe, part of the MAGNA Group, this new sensor forms a vital part of the so-called active bonnet. The company chose this high-performance type of Hytrel® for its effective combination of properties, including good aging resistance and very good elastic behaviour at temperatures from 85 °C to –40 °C.

The sensor strip, between 1,1 and 1,4 metres long, depending on the model, is located between front bumper and radiator. During its whole working life it is exposed to water from road and rain, road salt solutions, dust and wide temperature variations. “Due its nearness to the radiator and as a result of solar radiation it may have to work at up to 85 °C; in winter it may be at –40 °C,” says Ralf Konnerth, Component Manager at Magna Electronics Europe. “We looked for a material that would ensure the sensor’s reliable operation at all times and under all conditions. Hytrel® met these demanding requirements. This plastic has good aging resistance, is robust, and keeps its elasticity even at low temperatures, which is vital for the sensor’s operation.”

Due to the part’s length, the two strips of Hytrel® forming the outer skin are produced by means of cascade injection moulding. Compliance with very close production tolerances is a substantial prerequisite for the sensor’s reliable operation. DuPont gave Magna Electronics Europe substantial technical support. “DuPont’s technical experts helped us with their own tests to determine the optimum injection moulding parameters and tool design,” adds Konnerth. “We also received valuable guidance how to assemble the sensor’s ‘inner life’—an optic fibre which is embedded in polyurethane foam—which is adhered onto the two halves of the outer skin.” The plastics surfaces are given a pre-treatment to improve the adhesion of the PU foam to the Hytrel®.

Magna Electronics Europe’s pedestrian protection sensor is currently installed in the Jaguar XK and Citroën C6. These two upmarket models are the first to offer ‘active bonnet’ technology. Other models will follow.

Background information: How the ‘active bonnet’ works

The sensor-operated ‘active bonnet’, one of the latest developments in automotive design, is intended to improve pedestrian safety. Inside the sensor strip, which is installed between the front bumper and the radiator, is a soft polyurethane (PU) foam in which an optic fibre made of polymethylmethacrylate (PMMA) is embedded. A light-emitting diode (LED) launches light impulses to the optic fibre. The LED is synchronised with a receiver at the other end of the sensor strip. The receiver registers the amount of light that actually arrives and constantly compares it with the amount of light emitted. If an object impacts the sensor strip, attenuation in the optic fibre increases and the amount of light received becomes less than the amount emitted. From the difference between the two, electronic measuring equipment connected to the sensor calculates the force of the impact. From the progression of the force over time the electronics can draw a conclusion as to the nature of the impacting object. It does this on the basis of an algorithm developed in the course of many tests. If it concludes that the object was a person, it ignites pyrotechnic actuators which within about 40 ms lift the bonnet a few centimetres. This increases the distance of the impacting body from the hard motor components, thus absorbing more energy. It also changes the angle in such a way that a pedestrian will not strike the windscreen with his head. This device is effective at speeds up to about 45 km/h.

Magna Electronics Europe, a wholly-owned subsidiary of MAGNA International, is the MAGNA Group’s centre of competence for vehicle safety and for the development of complete vehicle modules. It develops simulates and tests modular and functional systems in one of the most modern development and testing centres in the world. In the last ten years this source of innovation has created a reputation for itself as a reliable and flexible development partner for all major European automotive companies, especially in the domain of passive vehicle safety.

The DuPont Engineering Polymers business manufactures and sells Crastin® PBT and Rynite® PET thermoplastic polyester resins, Delrin® acetal resins, Hytrel® thermoplastic polyester elastomers, DuPont™ ETPV engineering thermoplastic vulcanizates, Minlon® mineral reinforced nylon resins, Thermx® PCT polycyclohexylene dimethyl terephthalate, Tynex® filaments, Vespel® parts and shapes, Zenite® LCP liquid crystal polymers, Zytel® nylon resins and Zytel® HTN high-performance polyamides. These products serve global markets in the aerospace, appliance, automotive, consumer, electrical, electronic, healthcare, industrial, sporting goods and many other diversified industries.

DuPont is a science-based products and services company. Founded in 1802, DuPont puts science to work by creating sustainable solutions essential to a better, safer, healthier life for people everywhere. Operating in more than 70 countries, DuPont offers a wide range of innovative products and services for markets including agriculture and food; building and construction; communications; and transportation.

The DuPont Oval Logo, DuPont™, The miracles of science™ and all product names denoted with ® are registered trademarks or trademarks of DuPont or its affiliates.

Media Contact

More Information:

http://www.dupont.comAll latest news from the category: Automotive Engineering

Automotive Engineering highlights issues related to automobile manufacturing – including vehicle parts and accessories – and the environmental impact and safety of automotive products, production facilities and manufacturing processes.

innovations-report offers stimulating reports and articles on a variety of topics ranging from automobile fuel cells, hybrid technologies, energy saving vehicles and carbon particle filters to engine and brake technologies, driving safety and assistance systems.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…