CFD has it all wrapped up

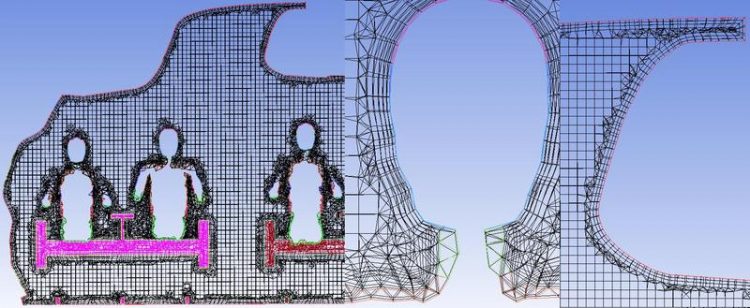

This diagram clearly shows just how tightly the grid enmeshes the virtual test subjects, or mannequins. Fraunhofer IBP

Scientists from the Fraunhofer Institute for Building Physics IBP want to understand every little detail, and so have every millimeter covered. Because they know their test person’s exact measurements and understand how these change in different positions.

The meshed grid in question consists of a million or more cells and took the scientists several weeks to knit around their test subject. How fortunate, then, that in this case the volunteers aren’t real people, but characters in a computational fluid dynamics (CFD) simulation. CFD is used whenever scientists and engineers need to understand and predict the flow behavior of fluids such as air, water and oil. It’s a technique that Sebastian Stratbücker, head of the Simulation group, and his team mainly use when investigating issues relating to indoor climate. In most cases, this involves looking at air and the way it behaves in enclosed spaces. “Our simulations help to optimize the indoor climate for people and technical equipment,” explains Stratbücker. “Evaluation parameters include thermal comfort, energy efficiency, humidity, CO2 and pollutant concentration.”

But what do we need CFD simulations for anyway? “In most cases, taking a trial and error approach just isn’t practicable,” explains Stratbücker. “Even in terms of setting up the test, it would often prove far too expensive and labor-intensive.”

Say you want to construct a new building, for example. The planning phase is all-important, and requires those involved to make a lot of important decisions before work has even begun, such as which ventilation system to install. Planners need solutions that will help them make such choices in advance; they have to be able to determine whether the system they intend to install is up to the job while also being efficient and ideally cost-effective at the same time.

CFD offers just such assistance, and enables planners to measure and evaluate rooms in great detail with the help of the grid described above. This system allows them to call up the indoor climate conditions for any point in the room at any given point in time, highlighting factors ranging from air velocity, temperature and pressure through air exchange rate and the concentrations of specific substances in the air.

Of course, the boundary conditions for the simulation must be clearly defined; these parameters are often determined by measurements taken in laboratories or in field tests. Fraunhofer IBP scientists also use their own specially developed DressMAN 2.0 measuring system for this purpose. In other cases, they rely on their own databases of building physics reference data, types of construction, building services, and usage profiles. They draw additional data from their customers’ plans. All this allows the computer program to evaluate factors such as the geometry of the space in question, including any air inlets and outlets, exchanges of air between the outside and inside environments, the heating and cooling capacity of the chosen system, the periods when the space is in use, the materials used in its construction, and many more features.

Even the physical properties of the windows or the type of clothing worn by the people using the building can be taken into account if required. “It goes without saying that CFD is also quite an intensive process, but one that’s worth it compared to the trial-and-error principle, as it means we avoid making mistakes from the outset,” Stratbücker explains, adding: “Simulating different scenarios lets us work up a range of proposed solutions and analyze them, so we end up with the optimum system design.”

Of course, this does not just apply to the planning phase of new constructions. Fraunhofer researchers use CFD to identify and develop solutions to problems that arise in existing buildings, too.

Possible applications for CFD also extend beyond the realm of buildings; Stratbücker and his team use this form of flow simulation to analyze and evaluate aircraft and motor vehicle interiors as well. Much of the validation testing for simulations is conducted at the IBP’s Flight Test Facility FTF, a one-of-a-kind test site in Holzkirchen south of Munich. In return, the scientists applied CFD beyond Fraunhofer IBP’s usual setting of air flow simulations when they optimized numerous system components for the FTF’s new Ground Thermal Test Bench so it could be brought into service last year.

In order for the aircraft calorimeter (ACC) at the FTF to simulate the most extreme conditions such as thermal shock (rapid changes of temperature), the cooling and heating functions along the aircraft’s outer skin had to work without a hitch. The Simulation group used CFD to optimize the Ground Thermal Test Bench’s coolant tank and the recirculation of the cooling agent inside it in such a way that the liquid is cooled to exactly the required temperature before being fed back to the aircraft.

This demonstrates how flow simulation can benefit individual components, such as those in a ventilation system, as well as large systems, such as entire rooms. “We use CFD in any situation where we’re not certain if the system works in the way we think it should,” says Stratbücker. “But we also use other methods, depending on the issue we’re addressing.” For instance, particle image velocimetry (PIV) can be used to measure and visualize flow field velocities – which means it can help to verify CFD results at critical points.

IBP scientists developed VEPZO, the VElocity Propagating ZOnal Model, in order to be able to quickly evaluate indoor air flow patterns and temperature distributions. The model can evaluate ventilation concepts and visualize them at a local resolution. “We use it whenever air node models are too basic a solution and CFD too sophisticated. With VEPZO, we can demonstrate fairly quickly the effect that factors can have, such as planting concepts or a heating system that adjusts according to whether a room is empty or occupied.”

Stratbücker and his colleagues are already looking forward to using CFD in some exciting new projects. For instance, heating the interiors of old church buildings is often a big problem. Heating systems are generally used only on a temporary basis, and the heating effect is instantly lost to the large spaces. “If the system were tailored to requirements and designed according to users’ local needs, then a large church could be heated in a user-friendly manner without excessive heat loss. CFD can simulate how this might work in practice.”

http://www.ibp.fraunhofer.de/en/Press/Research_in_focus.html

Media Contact

All latest news from the category: Architecture and Construction

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…