Vortex rings may aid cell delivery, cell-free protein production

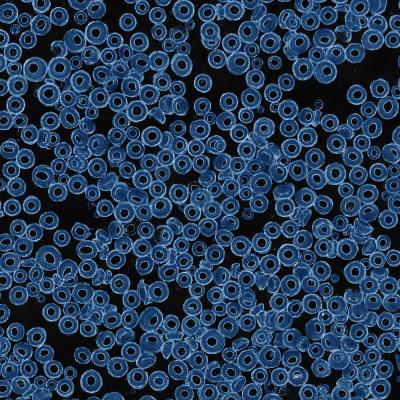

A microscopic image of doughnut-shaped microparticles, made from silica nanoparticles through vortex ring freezing. This work is detailed in a paper published on Aug. 4 in Nature Communications. Credit: Duo An/Cornell University

Add vortex ring freezing to that long list of “accidents.”

Duo An, a doctoral student in the labs of both professor Dan Luo and assistant professor Minglin Ma, in the Department of Biological and Environmental Engineering, was an undergraduate from China doing an internship at Cornell when he stumbled upon a phenomenon that has the potential to greatly improve cell-free protein production and cell delivery, particularly for Type 1 diabetes patients.

A group headed by Luo and Ma has published the paper, “Mass production of shaped particles through vortex ring freezing,” which was released online Aug. 4 in Nature Communications. An is lead author.

Vortex rings are ubiquitous in nature – a mushroom cloud of smoke is one example – and the ring's evolution exhibits a rich spectrum of complicated geometries, from spherical to teardrop to toroidal (doughnut-shaped). The researchers used these features to control and mass produce inorganic and organic particles via an electrospraying process, whereby a multitude of vortex ring-derived particles (VRPs) can be produced, then frozen at precise time points. The group reported they could produce 15,000 rings per minute via electrospraying.

They found controlling the shape and speed of the spray, as well as the speed of the chemical reaction, can yield different structures.

“We can tune both of these timescales, and control at which stage we can freeze the structure, to get the results we want,” An said.

While working in Luo's lab during a summer internship, An was making nanoclay hydrogels – injecting one solution into another to create a gel. But for this particular procedure, instead of direct injection, he dripped one solution into another. When the first solution entered the second, it created vortex-ring particles.

It wasn't until two years later, while working in Ma's lab, that he recalled the vortex rings he'd created and wondered if that concept could be applied to Ma's work with microcapsules and cell therapy. The Ma lab focuses on cell delivery for Type 1 diabetes patients.

Ma admitted that the concept of using a doughnut-shaped encapsulation hadn't occurred to him, but made perfect sense.

“We knew the concept that a doughnut shape is better, but we never thought of making it until we saw it [from An],” Ma said.

An advantage of the doughnut-shape encapsulation over a spherical-shaped one is shorter diffusion distance – the distance the encapsulated particle must travel to escape the capsule – while at the same time maintaining a relatively large surface area.

This concept could pave the way for other as-yet-unknown applications of vortex ring freezing, according to Luo.

“Our hope is that this type of material in these shapes can be used much more extensively in other labs for whatever they're trying to do,” he said. “There is a whole field devoted to just particles, but by default, they are all thinking in terms of spherical particles. Hopefully, this will add to that field of study.”

Ma, who earlier this year won a Hartwell Individual Biomedical Research Award for his work on juvenile diabetes, cited the work of collaborators Ashim Datta, professor of biological and environmental engineering, and Paul Steen, the Maxwell M. Upson Professor of Engineering in the Robert Frederick Smith School of Chemical and Biomedical Engineering. Datta's lab did the simulation work, and Steen's group provided key theoretical input.

“Their contributions put this work on much more solid ground,” Ma said. “We now better understand the mechanism behind it, and can more purposefully design these particles in the future.”

###

Other collaborators included graduate students Alex Warning, Kenneth Yancey, Chun-Ti Chang and Vanessa Kern.

This work was supported by grants from the American Diabetes Association, the SUNY Research Foundation, the National Institutes of Health and the National Science Foundation (NSF). The research made use of the Cornell Center for Materials Research Shared Facilities, which are supported by the NSF.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…