Problem: Implant Infection. Solution: Nanotech Surfaces

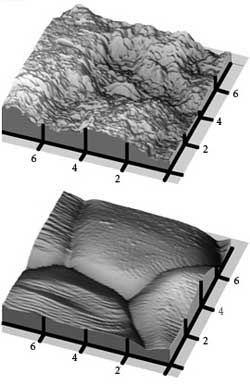

<b>Microcraters and nanosurfaces</b><br><br>A rougher terrain engineered on the nanoscale (top) promoted bone adhesion and inhibited bacterial growth much better than the smoother surface engineered on the microscale (bottom). Units are in microns. Image: T.J. Webster

Orthopaedic implants help millions of Americans stay active. But these medical devices are prone to infection, forcing patients back to surgery for repair or replacement. Now, for the first time, a team of engineers has shown that zinc or titanium oxide nanosurfaces can reduce the presence of bacteria, a technique that can be applied to implants to reduce the number of these costly and debilitating infections.

Thomas Webster, an associate professor of engineering at Brown, led the research. Results are published in the Journal of Biomedical Materials Research.

“We’ve found a method of coating implants that discourages bacteria growth,” Webster said, “and it does so significantly. The hope is that this technique will lead to safer, longer-lasting implants.”

According to the American Academy of Orthopaedic Surgeons, 766,100 Americans underwent surgery for hip, knee and shoulder replacements in 2002. During typical procedures, surgeons remove an arthritic or damaged joint and replace it with an artificial one. In about 1 to 2 percent of cases, the implant gets infected. The most common culprit: Staphylococcus epidermidis. Found on skin or in mucous membrane, S. epidermidis can enter a surgical wound and adhere to an implant. The bacteria multiply, causing a slimy layer, or biofilm, to form around the implant. The slime is tough stuff, acting as a physical and chemical barrier that resists antibiotics. The result is additional surgery to clean the implant or replace it outright.

Webster, along with former Purdue University colleagues Gabriel Colon and Brian Ward, knew that abrading or coating implants to produce microscopic bumps, which create a sand-papery surface, aid in bone growth. This helps anchor the implant in the body and extends its life. Some artificial joints now sport these microstructured surfaces.

But the team wondered if smaller peaks and craters – ones that measure on the nanometer scale – would work even better. And how would bacteria react? So they experimented.

The engineers chose zinc and titanium oxides as their materials. Zinc oxide is a well-known antimicrobial agent. Titanium oxide, strong and light, is a commonly used in implants. Engineers took nanoparticles of these ceramics and pressed them into dime-sized discs. They took microparticles of these same materials and made more discs. Discs with nanostructured surfaces had bumps that measured only .023 microns in diameter. Discs with microstructured surfaces had bumps that measured about 5 microns in diameter. Under a microscope, the surface differences are extreme; the nanostructured discs look like saw-toothed mountains, the microstructured discs look like smooth plateaus.

The engineers put S. epidermidis on the discs and waited an hour. Then they counted the bacteria. The results were dramatic. Microstructured zinc oxide discs were host to 1,000 times more bacteria than the nanostructured zinc oxide discs. Similar, but less striking, results were duplicated on titanium oxide discs.

The engineers conducted similar experiments with bone-forming cells and found that twice as many of these cells grew and formed bone on nanostructured discs. Other indicators of healthy bone growth, such as collagen synthesis, were also stronger with nanostructured discs.

“Surface area seems to be key,” Webster said. “With the nanostructured surfaces we created, surface area increased by 25 to 35 percent. We think that this additional area, along with the unique surface energetics of these nanomaterials, gave bone-forming cells more places to adhere. But with bacteria, increased surface area may work the other way, exposing the bugs to more of the germ-fighting properties of the zinc oxide.”

The National Science Foundation funded the work.

Media Contact

More Information:

http://www.brown.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…

Making diamonds at ambient pressure

Scientists develop novel liquid metal alloy system to synthesize diamond under moderate conditions. Did you know that 99% of synthetic diamonds are currently produced using high-pressure and high-temperature (HPHT) methods?[2]…

Eruption of mega-magnetic star lights up nearby galaxy

Thanks to ESA satellites, an international team including UNIGE researchers has detected a giant eruption coming from a magnetar, an extremely magnetic neutron star. While ESA’s satellite INTEGRAL was observing…