Supercool! Model unscrambles complex crystallization puzzle

To the wonderment—and the befuddlement—of scientists, the patterns that form as plastics, metals and many other materials crystallize can vary incredibly, ranging from sea-urchin-like spheres to elaborate tree-like branches.

Now, Hungarian and National Institute of Standards and Technology scientists report in the September issue of Nature Materials* that they have developed a way to predict the polycrystalline microstructures that will form as complex liquid mixtures cool and solidify. Ultimately, the team’s new simulation tool could help manufacturers of everything from plastic bags to airplane wings to design new products with improved strength, durability and other properties.

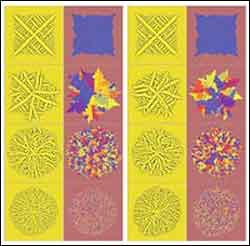

Images generated with the team’s mathematical model match up almost feature for feature with the seemingly random crystal patterns formed in experiments as temperatures or other processing variables are modified. The model accurately predicts how both impurities (or additives) and process differences affect the sizes, shapes and orientations of crystals that form during the so-called supercooling process.

Whether initiated by “dirt” or by processing conditions, the resulting patterns can be strikingly similar. This “duality in the growth process,” notes NIST’s James Warren, may help explain why polycrystalline growth patterns are so prevalent in polymers and other materials derived from complex mixtures.

Findings based on the model indicate that instabilities along the boundary between liquid and solid areas during solidification effectively clash with the otherwise orderly process of crystallization. Tiny crystals-in-the-making move and position themselves along the growth front, assuming an orientation peculiar to the energy conditions at their location. Varying local conditions produce crystals in seemingly disordered arrays, accounting for the rich diversity of microstructural patterns.

Media Contact

More Information:

http://www.nist.govAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…