DuPont launches two new grades of Entira™ antistatic additives

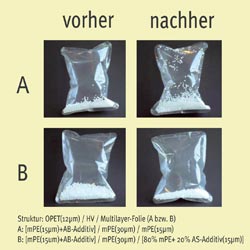

Picture: DuPont <br>DuPont™ Entira™ Antistat is a family of new, permanent antistatic additives, the effect of which is clearly seen above: In a bag without Entira™ Antistat, the polystyrene balls stick to its walls of the bag when it is rubbed with a cloth (top). With Entira™ Antistat there is no static charge to attract the balls (bottom).

These new additives, which are ideal for use with polyolefins and other polymers, ensure permanent, anti-static dissipation and provide superb aesthetics, clarity, non-yellowing and dust free protection for a variety of demanding packaging needs, from cosmetics to industrial goods to sensitive electronics components.

Entira™ Antistat SD 100 and Entira™ Antistat 500 have a number of distinct advantages over diffusive antistatic agents. Unlike these solutions, which are often concentrated on the product surface and can wear off due to rubbing, water or age, the new Entira™ Antistat grades are integrated directly into the product, adding immediate and permanent anti-static action, and a smooth, transparent surface appearance that allows better adhesion and printability. They also prevent yellowing due to age, can be used in a discrete layer without migrating to other layers and help to minimize die build-up. Additionally, when used with polyolefins, Entira™ Antistat is currently the only permanent additive on the market to deliver both anti-static properties and transparency in the final product.

“The addition of Entira™ Antistat SD 100 and Entira™ Antistat 500 to our portfolio of Entira™ resin modifiers and additives provides our customers with a competitive advantage by effectively reducing and dispelling static, which can damage finished products or degrade their appearance,” said Steven P. Wilkinson, global marketing manager, Industrial Goods, DuPont Packaging & Industrial Polymers. “We are very pleased to offer these new grades of antistatic agents that meet our customers’ very diverse and stringent performance requirements and help maximize shelf appeal for end-users.”

Entira™ Antistat SD 100 can be used in electronics packaging to reduce sparks that could damage equipment. It is also fully approved for use with food and can minimize dusting that can prevent a good product seal. Entira™ Antistat 500, which is currently available for sampling, can be used at higher processing temperature conditions.

For more information about these new product grades, please visit www.entira.dupont.com.

DuPont Packaging and Industrial Polymers is a world-class manufacturer of high-performance resins and films for a variety of packaging and industrial applications. Its best known ethylene copolymer products include Surlyn® resins for packaging and industrial applications, Bynel® coextrudable adhesives, Selar® PA amorphous polyamide barrier resins, Nucrel® acid copolymers, Elvax® EVA copolymers, Elvaloy®, Elvaloy AC®, Entira(TM) and Fusabond® modifiers, and Vamac® ethylene acrylic elastomers.

DuPont is a science-based products and services company. Founded in 1802, DuPont puts science to work by creating sustainable solutions essential to a better, safer, healthier life for people everywhere. Operating in more than 70 countries, DuPont offers a wide range of innovative products and services for markets including agriculture and food; building and construction; communications; and transportation.

The DuPont Oval Logo, DuPont™, The miracles of science™ and all product names denoted with ® are registered trademarks or trademarks of DuPont or its affiliates.

Media Contact

More Information:

http://www.entira.dupont.comAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…