Cell on a Chip Reveals Protein Behavior

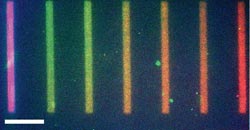

Protein interaction on a chip: Red proteins concentrated more on the right, farther from the chip-bound genes, while green proteins are more highly concentrated on the left, closer to the genes that encode them<br>

For years, scientists around the world have dreamed of building a complete, functional, artificial cell. Though this vision is still a distant blur on the horizon, many are making progress on various fronts. Prof. Roy Bar-Ziv and his research team in the Weizmann Institute’s Materials and Interfaces Department recently took a significant step in this direction when they created a two-dimensional, cell-like system on a glass chip.

This system, composed of some of the basic biological molecules found in cells – DNA, RNA, proteins – carried out one of the central functions of a living cell: gene expression, the process by which the information stored in the genes is translated into proteins. More than that, it enabled the scientists, led by research student Yael Heprotein yman, to obtain “snapshots” of this process in nanoscale resolution.

The system, consisting of glass chips that are only 8 nanometers thick, is based on an earlier one designed in Bar-Ziv’s lab by Dr. Shirley Daube and former student Dr. Amnon Buxboim. After being coated in a light-sensitive substance, the chips are irradiated with focused beams of ultraviolet light, which enables the biological molecules to bind to the substance in the irradiated areas.

In this way, the scientists could precisely place DNA molecules encoding a protein marked with a green fluorescent marker in one area of the chip and antibodies that “trap” the colored proteins in an abutting area. When they observed the chips under a fluorescence microscope, the area in which they had placed the antibodies turned a glowing bright green. This meant that the DNA instructions had been copied into RNA molecules, which were in turn translated into fluorescent green proteins. The green proteins were then ensnared by the antibodies.

Next, the scientists asked whether their cell-like system could reproduce complex structural assemblies of naturally-occurring proteins. This time, they attached a viral gene to the chips’ surface encoding a protein that can self-assemble into a nanotube. With the help of Dr. Sharon Wolf of the Electron Microscopy Unit, they observed a forest of minuscule tubes sprouting from the antibody area under an electron microscope.

The researchers then sought a way to produce and trap multiple proteins simultaneously by confining each protein in the area of its gene on the chip. On top of the chip to which the DNA encoding green proteins was bound, the scientists added a solution with a second gene encoding a red protein. The resulting red and green proteins competed for binding on the antibody traps, yielding a graded spatial separation in which the antibodies closest to the green genes had the highest concentration of green protein, with red concentrations rising farther afield. The results of this research recently appeared in Nature Nanotechnology.

Bar-Ziv: “We have shown that it is possible to build a protein 'production line' outside of the cell and use it to observe a spectrum of protein activities.” In the future, such a system may move from enabling the observation of proteins to providing the basis for techniques to create complex, active protein structures on demand.

Prof. Roy Bar Ziv’s research is supported by the Yeda-Sela Center for Basic Research; and the Carolito Stiftung.

Media Contact

More Information:

http://www.weizmann.ac.ilAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…