Conference on Laser Polishing – LaP: Fine Tuning for Surfaces

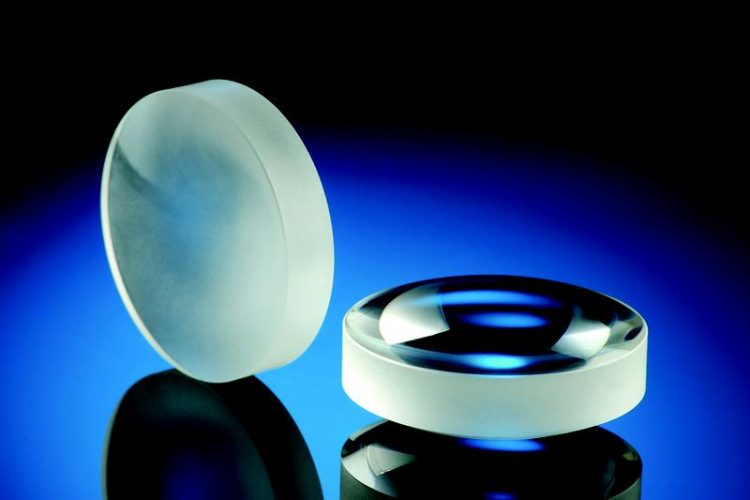

Laser-polished sphere made out of BK7. © Fraunhofer ILT, Aachen, Germany.

Laser polishing is a relatively new process that has only been used for selected fields of applications in the industry: for example, machining metals for toolmaking and automotive engineering, as well as processing glass optics.

International conference

Prior to 2014, the pioneers of this process did not have the opportunity to exchange research results in a wider and international context. That is why Fraunhofer ILT launched the first “Conference on Laser Polishing – LaP” in 2014, which has been held every two years since then and has become the international meeting place for laser polishing experts.

“If you look at the specialist literature, more than 80% of the research groups working on the topic worldwide have attended the LaP conference so far,” states Dr. Edgar Willenborg, Head of the Laser Polishing Group at Fraunhofer ILT.

“Researchers from all over the world – from China, Russia, Canada, many European countries and the USA – have come to the conference. That's why English is the conference language, also at the third LaP”. While the majority of the 20 lectures come from academia, the participants come roughly equally from industry and research.

Focus on technical surface properties

“Researchers are concentrating more and more on the properties of surfaces relevant to specific applications,” says the expert. “In the beginning, it was primarily about lowering the roughness, but now more and more functional tests and application tests are being added”.

For example, users would like to eliminate microdefects to increase the lifetime of a metallic component, or to polish particularly complex optical glass surfaces. One of the new applications, covered for the first time at LaP, is the laser polishing of additively manufactured components made of plastic.

Many speakers have one goal in common: to create a broad, scientific basis for the industrial use of laser polishing. Willenborg: “With hand polishing, it is possible to achieve a lower roughness on metallic components, but it is much slower than laser polishing”.

With the laser, on the other hand, complex geometries can be polished automatically, reproducibly and significantly faster. While the quality of laser polishing for many applications is already sufficient, the processing speed must be increased even more. “Accelerating laser polishing is currently an important trend, as it makes the process economical for a wide range of applications,” says Willenborg.

Dr.-Ing. Edgar Willenborg

Group Manager Polishing

Telephone +49 241 8906-213

edgar.willenborg@ilt.fraunhofer.de

Media Contact

All latest news from the category: Event News

Newest articles

Red light therapy for repairing spinal cord injury passes milestone

Patients with spinal cord injury (SCI) could benefit from a future treatment to repair nerve connections using red and near-infrared light. The method, invented by scientists at the University of…

Insect research is revolutionized by technology

New technologies can revolutionise insect research and environmental monitoring. By using DNA, images, sounds and flight patterns analysed by AI, it’s possible to gain new insights into the world of…

X-ray satellite XMM-newton sees ‘space clover’ in a new light

Astronomers have discovered enormous circular radio features of unknown origin around some galaxies. Now, new observations of one dubbed the Cloverleaf suggest it was created by clashing groups of galaxies….