Precious coatings for plastic parts

Be they ball bearings in bicycles, slide bearings in the crankshafts of ships, or high-performance bearings in motor sports – bearings fulfill a wide range of functions. In many cases, they have to withstand enormous engine speeds and thermal loads, which places extremely high demands on the material from which the bearings and the associated bearing cages are made.

Research scientists at the Fraunhofer Institute for Mechanics of Materials IWM in Freiburg are working on the bearings of the future. They are equipping them with a very special coating that makes high-performance roller bearings, for example, even more durable and reliable than they already are.

The coating consists of diamond-like carbon (DLC). “Thanks to this coating, we can produce components that are much more robust than conventional elements, such as those made of uncoated plastic,” says IWM division director Dr. Sven Meier. “The coated bearings remain sturdy even if they are not sufficiently lubricated or if they run dry.”

Applying the DLC coatings to the parts requires a special process developed by the scientists at the IWM. “Our coating method is also suitable for geometrically complex parts, such as bearing cages,” Meier explains. The engineers have optimized the technique in such a way that even very thick DLC coatings – thicker than 20 micrometers – can be applied. “Our process enables us to generate targeted micro-structured coating systems, which in turn makes it possible to optimize the effect of lubricants and minimize friction and wear in the bearings. If required, we can also produce ultra-smooth surfaces.”

The researchers achieved the best coating results on components made of special plastic. Bearings made of this material achieve much higher engine speeds, develop less heat, and reach a much better service performance with the new coating than in uncoated form.

At present, the researchers are working on methods of developing coating processes specifically optimized for particular applications with the help of mathematical models. Their aim is to reduce the high costs currently required to develop such complex processes.

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

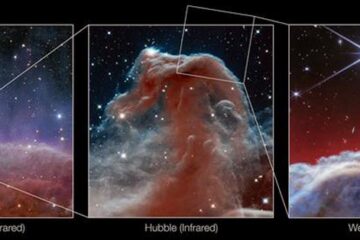

Webb captures top of iconic horsehead nebula in unprecedented detail

NASA’s James Webb Space Telescope has captured the sharpest infrared images to date of a zoomed-in portion of one of the most distinctive objects in our skies, the Horsehead Nebula….

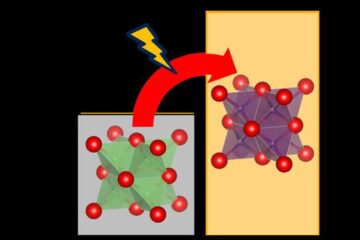

Cost-effective, high-capacity, and cyclable lithium-ion battery cathodes

Charge-recharge cycling of lithium-superrich iron oxide, a cost-effective and high-capacity cathode for new-generation lithium-ion batteries, can be greatly improved by doping with readily available mineral elements. The energy capacity and…

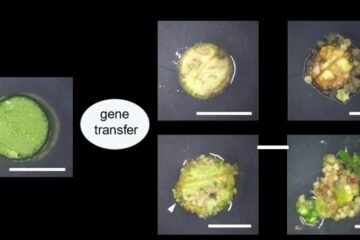

Novel genetic plant regeneration approach

…without the application of phytohormones. Researchers develop a novel plant regeneration approach by modulating the expression of genes that control plant cell differentiation. For ages now, plants have been the…