One light arc, two wires and a laser: HoDopp – high power deposition welding

Setup of the laser supported welding process. Photo: LZH

Since the dilution level is around 30 percent, several layers must be deposited, one on the other, until the protective covering is pure enough. Scientists at the Laser Zentrum Hannover e.V. (LZH) have now, as part of the project HoDopp, developed a laser-supported, light arc process, which achieves this in a single layer.

In the conventional process, the light arc burns between the wire electrode and the workpiece, and fuses both. For large area and multi-layer coatings, the process can take up to 24 hours per square meter. On the other hand, in the process used by the LZH, a light arc burns between two wires and melts them simultaneously.

The deposition rate can thus be increased to around 7.5 kg per hour. The laser beam, which is used in addition to this, assures layer adherence, and improves the form of the seam.

Low thermal stress on the components

Due to the support by the laser beam, the layer is deposited with a low penetration depth, and the dilution rate is thus under five percent. A further advantage of the process is low heat input. Component deformation is notably lower than with deposition welding using conventional GMAW, and the deposition rate can be increased by around 50%.

Since one layer replaces two or three conventionally deposited layers, time and material can be saved for inhomogeneous materials, by half to two-thirds. Thus, productivity and simultaneously the quality of the welding process can be drastically increased.

The project HoDopp: “High-power laser cladding using the twin-wire technique without light-arc transmission and with laser-assisted weld-penetration control” was financed by the Federal Ministry of Education and Research (BMBF). The project was completed at the end of 2014.

The LZH is presenting the process setup and finished components at the Hannover Messe 2015, at the joint stand of the State of Lower Saxony, hall 2, stand A08.

http://www.lzh.de/en/publications/pressreleases/2015/hodopp-high-power-depositio… – website of the press release with video

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

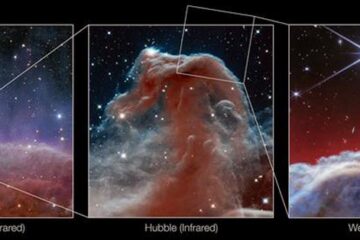

Webb captures top of iconic horsehead nebula in unprecedented detail

NASA’s James Webb Space Telescope has captured the sharpest infrared images to date of a zoomed-in portion of one of the most distinctive objects in our skies, the Horsehead Nebula….

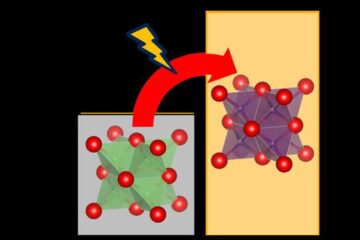

Cost-effective, high-capacity, and cyclable lithium-ion battery cathodes

Charge-recharge cycling of lithium-superrich iron oxide, a cost-effective and high-capacity cathode for new-generation lithium-ion batteries, can be greatly improved by doping with readily available mineral elements. The energy capacity and…

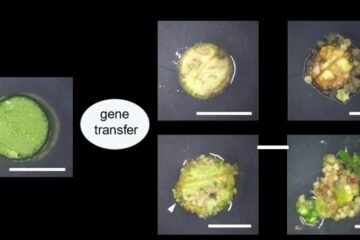

Novel genetic plant regeneration approach

…without the application of phytohormones. Researchers develop a novel plant regeneration approach by modulating the expression of genes that control plant cell differentiation. For ages now, plants have been the…