New Material Could Improve Fabrication of Nanoscale Components

A team of chemists at Penn State has developed a new type of ultrathin film, which has unusual properties that could improve the fabrication of increasingly smaller and more intricate electronic and sensing devices. The material, a single layer made from spherical cages of carbon atoms, could enable more precise patterning of such devices with a wider range of molecular components than now is possible with conventional self-assembled monolayers. The research is published in the current issue of the Journal of the American Chemical Society.

The molecules that make up the material have larger spaces and weaker connections between them than do components of conventional self-assembled monolayers. “The bonding and structural characteristics of this monolayer give us the opportunity to replace its molecules with different molecules very easily, which opens up lots of possibilities for both directed patterning and self-assembled patterning,” says Paul S. Weiss, professor of chemistry and physics.

One of the advantages of Weiss’s new monolayer material is that the characteristics of its high-quality structure can improve the precision of the lithography process in the fabrication of nanoscale devices. In this process, the monolayer sheet would sit on a gold substrate, to which other kinds of molecules bind after they displace some of the original monolayer’s carbon molecules. The molecules of the original monolayer then can function as a kind of corral to keep the replacement molecules from wandering. This controlling structure is an improvement over conventional methods, during which patterns deposited on a bare gold surface have a tendency to spread by diffusion.

“Because weak interactions hold them in place, the monolayer molecules can serve as easy-to-displace placeholders for other more strongly interacting molecules,” Weiss explains. “This property expands the range of molecules that can be incorporated into the monolayer structure.”

In addition to Weiss, the research team includes Penn State graduate students Arrelaine A. Dameron and Lyndon F. Charles. This research was supported by the Air Force Office of Scientific Research, Army Research Office, Defense Advanced Research Projects Agency, National Science Foundation, Office of Naval Research, and Semiconductor Research Corporation.

Media Contact

More Information:

http://www.psu.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Sensor measures oxygen content of breath

Oxygen saturation in the blood that is either too low or too high can cause physical harm or even death. This is why patients’ oxygen concentraions are monitored continuously in…

Laser immersion probe for smart inline monitoring of water and wastewater

A new type of laser-based immersion probe, which the Fraunhofer Institute for Laser Technology ILT in Aachen is testing as part of BMBF- and EU-funded projects with industrial partners and…

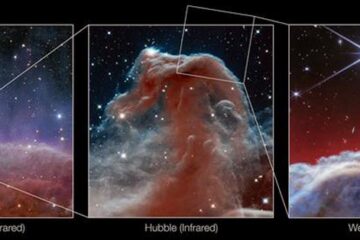

Webb captures top of iconic horsehead nebula in unprecedented detail

NASA’s James Webb Space Telescope has captured the sharpest infrared images to date of a zoomed-in portion of one of the most distinctive objects in our skies, the Horsehead Nebula….