A chip for environmental and health monitoring

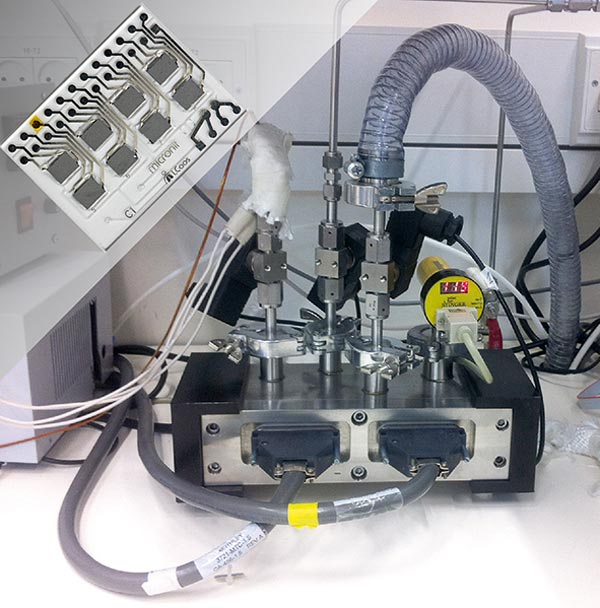

FAU scientists developed intelligent sensor arrays that can analyse complex gas mixtures. Now, they are aiming to integrate the sensor elements with all the electronics on a single chip. Image: Technion/Laboratory for nanomaterial-based devices

Combining different sensor components is a key factor

The project represents an extension of an earlier successful collaborative undertaking in which the Erlangen-based team developed the technological groundwork together with their Israeli colleagues. These include intelligent sensor arrays, which can analyse complex gas mixtures.

To do this, the scientists combined several sensor components which react to large numbers of molecules in non-specific but slightly different ways.

‘Based on the combined reactions of all sensor components, we can deduce the presence of a specific molecule,’ explains Prof. Silke Christiansen, who is working with Prof. Gerd Leuchs, Professor of Experimental Physics (Optics) at FAU and the director of the Max Planck Institute for the Science of Light. The researchers have already successfully tested the concept underlying the sensor in the diagnosis of cancer – but using a design which is not yet suitable for cost-effective mass production.

Two challenges – miniaturisation and compatibility

To produce their miniaturised sensor arrays, the researchers first need to overcome two challenges. Firstly, they have to integrate the three main components in a single chip – the gas-sensitive sensors, the transistors for processing the signals and artificial intelligence in the form of neural networks, which process the complex sensor signal patterns and evaluate them. The second problem is that the researchers are restricted in terms of the materials they can use.

‘In order to achieve industrial-scale mass production, the sensor arrays will have to be made on the large assembly lines that are already being employed for the extensive manufacture of microchips, but these are customised to the types of manufacturing processes needed to produce semiconductor devices. If we are to use them, only certain materials can be used, since atypical components can permanently contaminate these kinds of plants,’ said Christiansen.

FAU – an expert in material analysis and processing

The FAU team is working on the project – which has attracted total funding of €1.8 million – alongside three Israeli participants and a German partner from industry. The project partners are the Israeli semiconductor manufacturer Tower Semiconductor, Technion in Haifa, Tel Aviv University and the German semiconductor manufacturing plant construction company Singulus Technologies AG, based in Kahl am Main.

The scientists at the Chair of Experimental Physics (Optics) are contributing their expertise in the field of materials analysis and processing. ‘In our lab we will be investigating whether the materials we use actually work as they are supposed to, and how the production processes will need to be adapted to create sensor structures that function properly,’ explains Prof. Christiansen.

In addition, the researchers will be fine-tuning the functionality of the materials used. This will allow, for example, organic molecules for specific sensor applications to be applied to the substrate of the chip, which will provide characteristic sensor responses in specific areas of application, such as in the respiratory diagnosis of cancer or monitoring levels of harmful gases in the environment or workplaces.

Further information:

Uwe Mick

uwe.mick@fau.de

Media Contact

More Information:

http://www.fau.de/All latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…