Strong and ductile Damascus steels by additive manufacturing

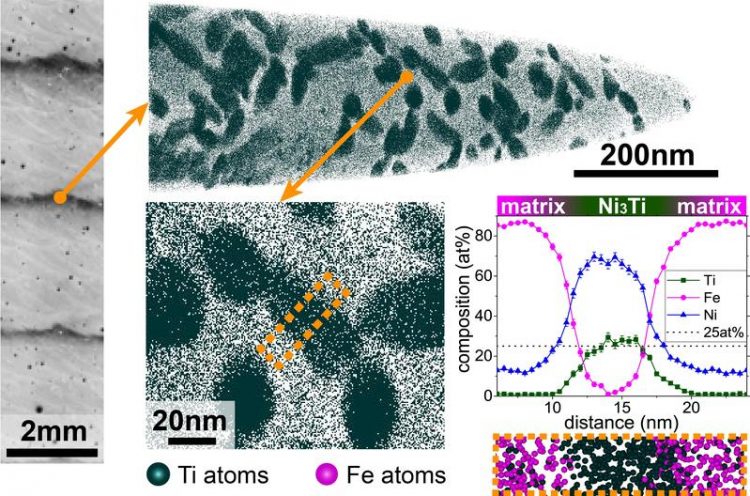

Atom probe tomography measurement showing the Ti-rich precipitates that are triggered by the intrinsic heat treatment during the additive manufacturing process in the dark, hardened layers. P. Kürnsteiner, Max-Planck-Institut für Eisenforschung GmbH

Dr. Philipp Kürnsteiner, Prof. Eric Jägle and their team at the Max-Planck-Institut für Eisenforschung (MPIE) designed, together with colleagues from the Fraunhofer Institute for Laser Technology, a new strong and ductile steel, imitating the layered structure of Damascus steels.

They were able to exploit the intrinsic heat treatment during additive manufacturing, thus saving time and costs of the usual post-process heat treatment. The scientists recently published their findings in ‘Nature’.

“We designed a new iron, nickel and titanium based steel that is tailor-made for additive manufacturing processes. This new steel is capable of exploiting advantages of directed energy deposition, such as the intrinsic heat treatment capability. By controlling the temperature and cooling rates, we were able to digitally control the alloys’ microstructure layer by layer and gained a maraging steel with adjustable properties”, explains Kürnsteiner, postdoctoral researcher in the groups “Alloys for Additive Manufacturing” (AAM) and “Atom Probe Tomography” and first author of the ‘Nature’ publication.

Directed energy deposition is one of the most popular additive manufacturing techniques. Samples are built from computer models in a fully digitalized manner by melting metallic powder with a focused laser beam. The layer by layer construction, typical for additive manufacturing processes, gave the chance to mimic the structure of Damascus steels.

Damascus steels gain their high strength and ductility through a structure of soft and hard layers, which is achieved through repeated folding and forging.

“Instead of folding and forging, we used the digital control over the process parameters. We exploited the complex thermal history of additive manufacturing, including cyclic re-heating to trigger the phase transformations needed for high strength and ductility: first, a formation of a nickel rich martensite microstructure transformed from austenite. Second, the formation of nickel-titanium precipitates, which leads to a hardening effect.”, explains Jägle, head of the AAM group and since January 2020 also professor at the Universität der Bundeswehr München.

The scientists gained control over the cooling-down of the sample via specific pause times that were introduced during the additive manufacturing process. This allowed to control the sequence of the two phase transformations and hence alternate between hardened and non-hardened regions. In order to study the complex and highly hierarchical microstructure of additively manufactured steels, a combination of different analytical techniques including electron backscatter diffraction and atom probe tomography was used.

This allowed to draw a complete picture of the microstructure ranging from hardened layers occurring on a millimetre length scale to solidification structures on a micrometre scale down to nanometre sized nickel-titanium precipitates that were triggered by the intrinsic heat treatment.

“Other conceivable possibilities to control the in situ heat treatment, besides tuning the pause length of the laser, could be tuning the laser power, its scan path or applying external heating and cooling methods. We are testing the different possibilities now together with our partners from the Fraunhofer Institute for Laser Technology.

This opens new doors to locally adjust the microstructure of complex three-dimensional parts if our approach is coupled with powerful process simulation software. Additionally, our approach is suitable to a wide range of alloys and additive manufacturing processes.”, explains Kürnsteiner.

The MPIE scientists were able to show that the intrinsic heat treatment during laser additive manufacturing gives the chance to locally adjust microstructures. The ability of manipulating the microstructure is best usable in alloys that can optimally react to the specific conditions of additive manufacturing, as shown for the newly developed Fe19Ni5Ti steel.

The aim is now to design more alloys that profit from the in situ precipitation hardening and local microstructure control provided by additive manufacturing. The opportunity to locally tailor microstructures and mechanical properties opens new possibilities for manufacturing. Tools or construction parts could be built with soft cores and hard outer skins without additional coatings or other hardening treatments.

Dr. Philipp Kürnsteiner, kuernsteiner@mpie.de

P. Kürnsteiner, M. B. Wilms, A. Weisheit, B. Gault, E. A. Jägle, D. Raabe: High strength damascus steel by additive manufacturing. In Nature 582 (2020) 515, doi.org/10.1038/s41586-020-2409-3

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…