How Intelligent Systems Are Changing the Workplace

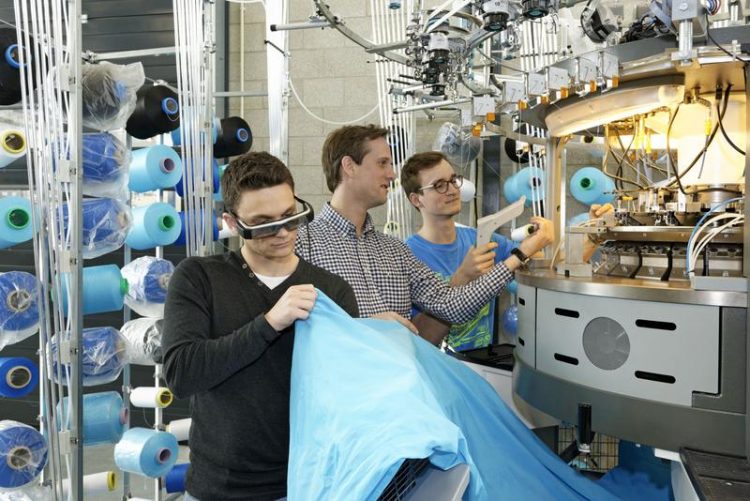

Marco Saggiomo, Yves-Simon Gloy und Alexander Weyers (von links) vom ITA der RWTH Aachen richten eine Webmaschine ein. Peter Winandy

Multiple machines rattle in one of the halls at the Institut für Textiltechnik or ITA. Many technical details and processes are tested on the machines, including the controls. Dr.-Ing. Yves-Simon Gloy demonstrates the operation that was current till now on a machine. A number of buttons must be pressed to attain the desired perameters.

“It's now simpler and better,” says Gloy, who then shows another machine with two students standing next to a small operator tablet. The menu consists of comprehensive and easily understood symbols, making it no longer necessary for workers to select the parameters themselves for the weaving process. An assistance system prescribes the optimal settings suitable for the material and machine. They are then confirmed simply with the press of a button.

Intelligent systems and increasing automation are leading to changes for employees in many fields within the textile industry. Under Gloy's project leadership a working group is investigating the interaction between social and technical innovations.

The department director at ITA and adjunct professor at Clemson University in South Carolina has found success with his concept in a funding competition held by the Federal Ministry of Research. Over the next five years a research group on the topic “Socio-Technical Systems in the Textile Industry” will be funded with 2.5 million Euros.

Technology Does Not Exclude People

Using implementation demonstrators, the use of existing solutions will be tested within the framework of Industry 4.0 in textile industry through interdisciplinary collaboration wiith industry and research partners. One goal is to enable more easier operation for an aging workforce. This doesn't just apply to the generation that grew up with analog machine systems, but rather all age groups, emphasizes Jacqueline Lemm. She works as a sociologist and academic staff member in the project.

“The average age of the workforce in the textile machine sector is over 50 and thus much higher than in other sectors. However there is also a large percentage of contract workers and migrants, who have to overcome language barriers.”

Workplaces with assistance systems can take individual skills into consideration and every person can be put in a position where they are able to find their way around more complex content. Lemm knows critics' arguments: “Many fear that the increasing automatization of production processes will wipe out jobs. We want to show that technology does not exclude people.”

Socio-Technical Systems

The research association wants to initiate production processes as socio-technical systems with people at the focus with their needs and skills. This includes handicap accessibility and that machines are not dependent on their location. According to the Aachen researchers, adapting text size, pictograms, or the inclusion of photos and videos that explain the work steps are all sensible details.

“We've already received a lot of positive feedback from the textile machine manufacturers,” reports Gloy. That's also founded in the competitive pressure of the industry, which only remains competitive internationaly through innovations. With approximately 65,000 employees, the textile industry is an important employer in Germany. As a result, the researchers in Aachen are using the contact with industry to test the suitability for everyday use of the systems they develop.

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…