Engineers roll up their sleeves – and then do same with inductors

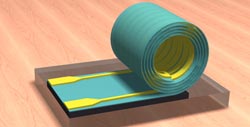

Photo by Xiuling Li <br><br>Illinois researchers developed a new design paradigm for inductors. Processed while flat, they then roll up on their own, taking up much less space on a chip.<br>

Three-dimensional rolled-up inductors have a footprint more than 100 times smaller without sacrificing performance. The researchers published their new design paradigm in the journal Nano Letters.

“It’s a new concept for old technology,” said team leader Xiuling Li, a professor of electrical and computer engineering at the University of Illinois.

Inductors, often seen as the sprawling metal spirals on computer chips, are essential components of integrated circuits. They store magnetic energy, acting as a buffer against changes in current and modulating frequency – especially important in radio-frequency wireless devices. However, they take up a lot of space. Inductance depends on the number of coils in the spiral, so engineers cannot make them smaller without losing performance.

In addition, the larger the area the inductor occupies, the more it interfaces with the substrate the chip is built on, exacerbating a hindering effect called parasitic capacitance. Researchers have developed some three-dimensional inductor structures to solve the dual problems of space and parasitic capacitance, but these methods are complex and use techniques that are difficult to scale up to manufacturing levels.

The new inductor design uses techniques Li’s group previously developed for making thin films of silicon nitrate, merely tens of nanometers in thickness, that roll themselves up into tubes. The research team used industry-standard two-dimensional processing to pattern metal lines on the film before rolling, creating a spiral inductor.

“We’re making 3-D structures with 2-D processing,” Li said. “Instead of spreading this out in a large area to increase inductance, we can have the same inductance but packed into a much smaller area.”

Using the self-rolling technique, the researchers can shrink the area needed for a radio-frequency inductor to a scant 45 microns by 16 microns – more than 100 times smaller than the area an equivalent flat spiral would require.

The design can be adjusted to fit target parameters including metal thickness and type, frequency, tube diameter and number of turns. According to Li, this technique could be used for capacitors and other integrated circuit elements as well.

Now, Li’s group is working to produce high-performance inductor prototypes, in collaboration with electrical and engineering professor Jose Schutt-Aine. Preliminary experimental data show strong correlation with the modeled designs.

“Once we have optimized this process, we should be able to make an integrated circuit with a completely different platform that could be much smaller,” Li said. “It’s an ambitious goal.”

The National Science Foundation and the Office of Naval Research supported this work. U. of I. visiting researcher Wen Huang, postdoctoral researcher Xin Yu, graduate student Paul Froeter and mechanical science and engineering professor Placid Ferreira were co-authors of this study. Li also is affiliated with the Beckman Institute for Advanced Science and Technology, the Micro and Nanotechnology Lab, and the Frederick Seitz Materials Research Lab, all at the U. of I.

Media Contact

More Information:

http://www.illinois.eduAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Sea slugs inspire highly stretchable biomedical sensor

USC Viterbi School of Engineering researcher Hangbo Zhao presents findings on highly stretchable and customizable microneedles for application in fields including neuroscience, tissue engineering, and wearable bioelectronics. The revolution in…

Twisting and binding matter waves with photons in a cavity

Precisely measuring the energy states of individual atoms has been a historical challenge for physicists due to atomic recoil. When an atom interacts with a photon, the atom “recoils” in…

Nanotubes, nanoparticles, and antibodies detect tiny amounts of fentanyl

New sensor is six orders of magnitude more sensitive than the next best thing. A research team at Pitt led by Alexander Star, a chemistry professor in the Kenneth P. Dietrich…