Supersonic Spray Delivers High Quality Graphene Layer

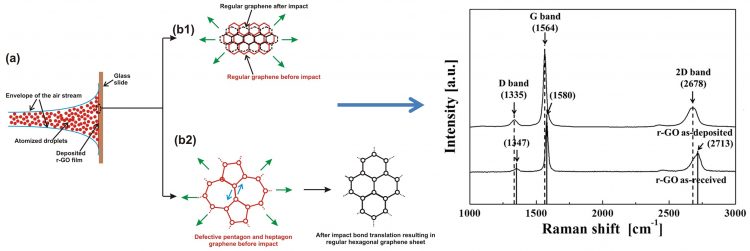

Photo credit: Suman Sinha-Ray Using a supersonic spray, graphene flakes with deformed pentagonal and heptagonal structures stretch on impact and spring into a perfect hexagonal graphene lattice. This opens the way to scale up from the microscopic to large scale applications.

Their study is available online in the journal Advanced Functional Materials.

Graphene, a two-dimensional wonder-material composed of a single layer of carbon atoms, is strong, transparent, and an excellent conductor of electricity. It has potential in a wide range of applications, such as reinforcing and lending electrical properties to plastics; creating denser and faster integrated circuits; and building better touch screens.

Although the potential uses for graphene seem limitless, there has been no easy way to scale up from microscopic to large-scale applications without introducing defects, says Alexander Yarin, UIC professor of mechanical and industrial engineering and co-principal investigator on the study.

“Normally, graphene is produced in small flakes, and even these small flakes have defects,” Yarin said. Worse, when you try to deposit them onto a large-scale area, defects increase, and graphene’s useful properties — its “magic” — are lost, he said.

Yarin first turned to solving how to deposit graphene flakes to form a consistent layer without any clumps or spaces. He went to Sam S. Yoon, professor of mechanical engineering at Korea University and co-principal investigator on the study.

Yoon had been working with a unique kinetic spray deposition system that exploits the supersonic acceleration of droplets through a Laval nozzle. Although Yoon was working with different materials, Yarin believed his method might be used to deposit graphene flakes into a smooth layer.

Their supersonic spray system produces very small droplets of graphene suspension, which disperse evenly, evaporate rapidly, and reduce the tendency of the graphene flakes to aggregate.

But to the researchers' surprise, defects inherent in the flakes themselves disappeared, as a by-product of the spray method. The result was a higher quality graphene layer, as found in the analysis by another collaborator, Suman Sinha-Ray, senior researcher at United States Gypsum and UIC adjunct professor of mechanical and industrial engineering.

The researchers demonstrated that the energy of the impact stretches the graphene and restructures the arrangement of its carbon atoms into the perfect hexagons of flawless graphene.

“Imagine something like Silly Putty hitting a wall — it stretches out and spreads smoothly,” said Yarin. “That’s what we believe happens with these graphene flakes. They hit with enormous kinetic energy, and stretch in all directions.

“We’re tapping into graphene’s plasticity — it’s actually restructuring.”

Other attempts to produce graphene without defects or to remove flaws after manufacture have proved difficult and prohibitively expensive, Yarin said.

The new method of deposition, which allows graphene to “heal” its defects during application, is simple, inexpensive, and can be performed on any substrate with no need for post-treatment, he said.

Yarin and his Korean colleagues hope to continue their successful collaboration and foster the development of industrial-scale applications of graphene.

Jung-Jae Park, Jung-Gun Lee and You-Hong Cha of Korea University; Sang-Hoon Bae and Jong-Hyun Ahn of Yonsei University; and Yong Chae Jung and Soo Min Kim of the Korea Institute of Science and Technology are co-authors on the paper.

Initial support for the collaboration between Yarin’s group at UIC and Yoon’s group at Korean University was provided by the Office of International Affairs Nuveen International Development Fund at UIC and by Korea University.

Media Contact

More Information:

http://www.uic.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…