Sensor technology can help uncover package tampering

Or tell you when it’s time to reel in that big fish

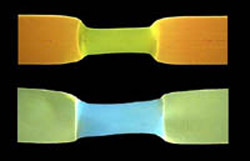

In a world with an intensified need for security, Case Western Reserve University researchers are developing materials that could make consumers less susceptible to product tampering or failures. Using a mixture of conventional polymers with small amounts of tailored fluorescent dyes, Case researchers have discovered that the dyes function as natural, molecular sensors, creating light-emitting polymer blends that show mechanical stress by changing colors when a material is deformed.

The technology could be useful in a variety of applications that range from early internal failure indicators in machinery and anti-counterfeiting elements to tamper-resistant packaging of food or medicines. Their research findings have appeared in several scholarly publications, most recently the Journal Chemistry of Materials. The research is being funded by the National Science Foundation and industry sources.

Christoph Weder, associate professor of macromolecular science and engineering at the Case School of Engineering, and graduate engineering students Brent Crenshaw and Jill Kunzelman are leading experiments in their lab on the Case campus to further this technology. Crenshaw, who has been working on the project for two years, points out that “only a small amount of dye is needed to make the polymer glow and that the polymer blend’s color contrast upon deformation is unparalleled.”

Kunzelman, a first-year student, says it would be gratifying one day to “see this technology used in everyday products.”

The thought isn’t far-fetched. Imagine being on a bass boat or hip-deep in a beautiful river doing some fishing when a colorful light emits from under the water – it’s either time to reel in that largemouth bass quickly or attach another lure to your fishing pole. Weder’s team created lab samples of a “smart” fishing line based on light-emitting polymer materials. The color of the line indicates when it’s been stressed too much. Weder, himself an avid fisherman, is especially proud of that work.

The research team reports that they have successfully blended tailored but readily available fluorescent dyes in minimal concentrations into standard polymers, such as polyethylene and polypropylene, and discovered that the dyes can serve as built-in sensors, which change their fluorescent color and allow the researchers to trace the deformation of the material.

Weder says he is excited by the application potential for this simple, yet groundbreaking technology his group discovered unexpectedly. “This is so trivial, yet novel at the same time,” Weder said. “No one has done this.”

Aside from Crenshaw and Kunzelman, Weder also employs two other graduate students, two postdoctoral researchers and four engineering undergraduates on his research team.

In addition, faculty and students in Case’s department of macromolecular science and engineering are working on more than 20 projects involving functional polymers, according to Alex Jamieson, professor and chair of the department. Those projects include polymers for membranes in fuel cells, electronic polymers with semiconducting properties and polymers for biofunctional applications, such as those related to drug delivery or biosensors. Weder’s deformation sensor technology project is one of the department’s forays into photonic polymers.

Jamieson says he’s intrigued by Weder’s research into deformation sensor technology. “It’s a novel approach to developing polymeric blends that are sensitive to deformation,” he said. “It’s a simple, yet very sensitive technique.”

Another exciting aspect of Weder’s research is how straightforward it may be to commercialize. “Some applicable dyes are affordable, easily made and can be used in concentrations as low as 0.1 percent,” he said. “There’s potential wherever polymers fulfill a structural function,” he added, citing tamper-evident packaging tape as an example. “We’re at a level of sophistication that would allow us to produce a simple product now.”

For now, these applications are still possibilities. But, Weder adds, with further commercial development, they could become reality in our everyday lives.

Media Contact

More Information:

http://www.case.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…