Preventing lithium loss for high-capacity lithium-ion batteries

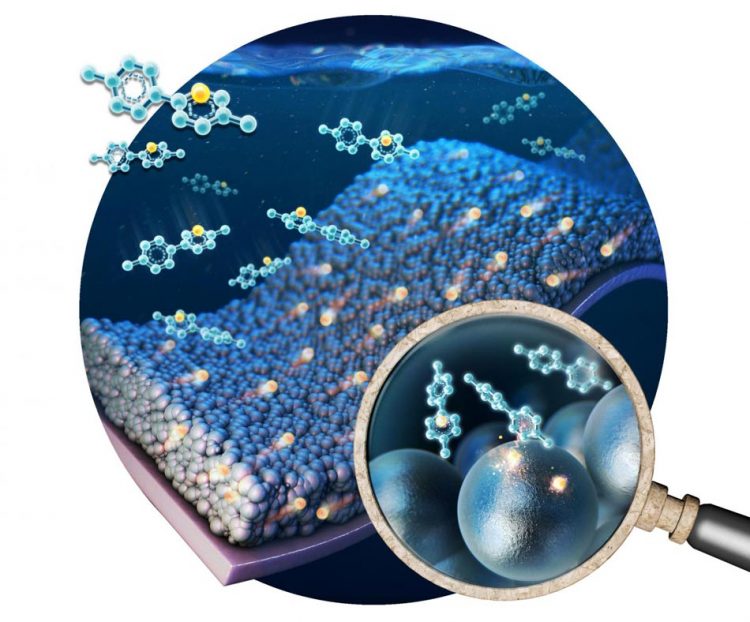

Korea Institute of Science and Technology (KIST) announced the development of a technology that provides a simple solution to a persistent issue associated with silicon-based anode (-) materials. Credit: Korea Institute of Science and Technology

A team of Korean researchers has developed a processing technology for maximizing energy densities of high-capacity batteries.

The joint research team, which consists of Dr. Lee, Minah of the Center for Energy Storage Research and Dr. Hong, Jihyun of the Center for Energy Materials Research, both of the Clean Energy Institute, Korea Institute of Science and Technology (KIST), announced the development of a technology that provides a simple solution to a persistent issue associated with silicon-based anode (-) materials.

Recently, silicon anode materials capable of storing four times more lithium ions than graphite anode materials in lithium-ion batteries have gained growing attention due to their potential to improve the mileage of electric vehicles.

But when charged in the initial cycle, a battery with a silicon-based anode loses more than 20% of the lithium ions it uses for electricity storage, which results in an issue of reduced battery capacity.

To resolve this issue, a method of “lithium pre-loading,” or “pre-lithiation,” which is adding extra lithium before battery assembly to compensate the lithium loss during battery cycling, has been studied. Methods applied so far such as using lithium powder have the drawbacks regarding a safety hazard and high cost.

Dr. Lee and Dr. Hong of KIST have developed a technology that enables the pre-loading of lithium ions using a lithium-containing solution rather than the lithium powder, to prevent lithium loss in a silicon-based anode.

Submerging an electrode in the tailored solution just for five minutes is enough to achieve a successful lithium pre-loading, by which electrons and lithium ions are inserted in the silicon-based anode through a spontaneous chemical reaction.

What made this simple process possible was that unlike the conventional method of adding lithium powder to an electrode leading heterogeneous lithium distribution, the tailored prelithiation solution rapidly seeps into an electrode ensuring homogeneous delivery of lithium into silicon oxide.

The prelithiated silicon-based anode developed by the research team loses less than 1% of active lithium in the first charge, yielding a high initial battery efficiency of 99% or higher. A battery manufactured with the prelithated anode exhibited an energy density 25% higher than that of a comparable battery using a graphite anode available on the market (406 Wh/kg ? 504 Wh/kg).

Dr. Lee, who headed the research, commented “By incorporating a *computational materials science technique into the design of an optimal molecular structure, we were able to improve the efficiency of a high-capacity silicon-based anode by leaps and bounds with the simple method of just controlling the solution temperature and reaction time.

As this technology is readily applicable to the **roll-to-roll process used in existing battery manufacturing facilities, our method has potential to achieve a breakthrough in the implementation of silicon-based anodes for practical batteries.”

Co-lead researcher Dr. Hong said, “This collaborative work could be realized because KIST encourages joint research between members from different research teams.” He went on to add, “this prelithation technology can increase the mileage of electric vehicles by a minimum of 100 km on average.”

###

*Computational materials science: A research method which predicts the composition and structure of a substance through computer simulations.

**Roll-to-roll: Application of the mass-printing technology to manufacturing

Another achievement of KIST's Center for Energy Storage Research has been presented mitigating dramatic volume change of a silicon-based anode during repeated battery cycling, by applying “fried” silicon with starch (Nano Lett. 2020, 20, 1, 625-635).

The research was supported by the Institutional Research Program of the Korea Institute of Science and Technology(KIST). This research was also supported by the Technology Development Program to Solve Climate Changes and the Hydrogen Energy Innovation Technology Development Program of the National Research Foundation of Korea. A research article reporting this technology will be published in an upcoming issue of Angewandte Chemie: International Edition, an international chemistry journal (IF: 12.257; top 9.593% of JCR), as an inside cover story.

Media Contact

More Information:

http://dx.doi.org/10.1002/anie.202002411All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Trotting robots reveal emergence of animal gait transitions

A four-legged robot trained with machine learning by EPFL researchers has learned to avoid falls by spontaneously switching between walking, trotting, and pronking – a milestone for roboticists as well…

Innovation promises to prevent power pole-top fires

Engineers in Australia have found a new way to make power-pole insulators resistant to fire and electrical sparking, promising to prevent dangerous pole-top fires and reduce blackouts. Pole-top fires pose…

Possible alternative to antibiotics produced by bacteria

Antibacterial substance from staphylococci discovered with new mechanism of action against natural competitors. Many bacteria produce substances to gain an advantage over competitors in their highly competitive natural environment. Researchers…