New Nanotech Technique for Lower-Cost Materials Repair

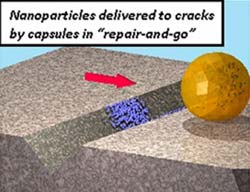

Todd Emrick, UMass Amherst<br>A recent materials repair discovery validates prior theory and may lead to significant conservation of material in diagnosing and repairing structural damage. The cartoon illustrates how nanoparticle-containing capsules roll or glide over damaged substrates, selectively depositing their nanoparticle contents into fractures.<br>

Their discovery is reported this week in the current issue of Nature Nanotechnology. The new technique has many practical implications, especially that repairing a damaged surface with this method would require significantly smaller amounts of material, avoiding the need to coat entire surfaces when only a tiny fraction is cracked, says team leader and UMass Amherst polymer scientist Todd Emrick.

“This is particularly important because even small fractures can then lead to structural failure but our technique provides a strong and effective repair. The need for rapid, efficient coating and repair mechanisms is pervasive today in everything from airplane wings to microelectronic materials to biological implant devices,” he adds.

At nano-scale, damaged areas typically possess characteristics quite distinct from their undamaged surrounding surface, including different topography, wetting characteristics, roughness and even chemical functionality, Emrick explains. He adds, “Anna Balazs predicted, using computer simulation, that if nanoparticles were held in a certain type of microcapsule, they would probe a surface and release nanoparticles into certain specific regions of that surface,” effectively allowing a spot-repair.

This vision of capsules probing and releasing their contents in a smart, triggered fashion, known as “repair-and-go,” is characteristic of biological process, such as in white blood cells, Emrick adds.

He says the experimental work to support the concept required insight into the chemistry, physics and mechanical aspects of materials encapsulation and controlled release, and was achieved by collaboration among three polymer materials laboratories at UMass Amherst, led by Alfred Crosby, Thomas Russell and himself.

The researchers show how using a polymer surfactant stabilizes oil droplets in water (in emulsion droplets or capsules), encapsulating nanoparticles efficiently, but in a manner where they can be released when desired, since the capsule wall is very thin.

“We then found that the nanoparticle-containing capsules roll or glide over damaged substrates, and very selectively deposit their nanoparticle contents into the damaged (cracked) regions. Because the nanoparticles we use are fluorescent, their localization in the cracked regions is clearly evident, as is the selectivity of their localization.”

Using rapid and selective deposition of sensor material in damaged regions, their innovative work also provides a precise method for detecting damaged substrates, he stresses. Finally, the new encapsulation techniques allow delivery of hydrophobic objects in a water-based system, further precluding the need for organic solvents in industrial processes that are dis-advantageous from an environmental standpoint.

Emrick says, “Having realized the concept experimentally, looking forward we now hope to demonstrate recovery of mechanical properties of coated objects by adjusting the composition of the nanoparticles being delivered.”

The work was supported by the National Science Foundations’ (NSF) Materials Research Science and Engineering Center on Polymers at UMass Amherst, an NSF Integrative Graduate Education and Research Traineeship (IGERT) award, the NSF Center for Hierarchical Manufacturing, the U.S. Department of Energy and its Office of Basic Energy Science.

Todd Emrick

413/577-1613

tsemrick@mail.pse.umass.edu

Media Contact

More Information:

http://www.umass.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…