Innovative powder revolutionises 3D metal printing

Mateusz Skalon has developed an innovative powder for 3D metal printing and is now working on its marketability © IMAT – TU Graz

Shorter production times, lower costs and fewer production faults. These are just some of the reasons why the metalworking industry is using additive methods more and more frequently. This is also reflected in the market for stainless steel powder used in additive manufacturing.

According to estimates, this is increasing by more than 30 per cent per year. Nevertheless, there is still room for expansion in 3D metal printing technology. Especially in selective laser melting (SLM), in which the component is built up in layers, the scope for design is limited with regard to construction and design.

The more complex the component, the more extensive support structures are necessary, for example to prevent possible overhangs from sinking during the printing process or other component deformations.

More design scope and lower printing costs

This is where the work of Mateusz Skalon starts, a researcher at TU Graz’s Institute of Materials Science, Joining and Forming. He has modified the particle surfaces of conventional 316L stainless steel powder so that the liquefied metal has a higher stability in the molten bath.

This allows greater freedom of design since components with small angles of inclination do not collapse during printing. This so-called NewGen SLM powder requires fewer supporting structures, which account for up to 20 percent of total printing costs. Savings in production are considerably reduced, as Skalon has calculated:

“Cost savings of up to 114 euros can be achieved per kilo of powder.” In this context Skalon refers also to the sustainability aspect. Surplus stainless steel powder can be easily recycled at the end of production, which creates additional material savings.

Processing system for innovative metal powder

Now Skalon wants to implement the research results in business with the support of TU Graz. In the framework of the current Spin-Off Fellowship of the Austrian Research Promotion Agency (FFG), he is scaling the modification process to bring it to market maturity. “We’ll be testing the powder on the most common laser melting systems in the next 16 months.

Building on this, we want to establish a production company in Austria directly after the Fellowship where purchased 316L stainless steel powder is modified and sold. Target groups will include manufacturers of highly complex metal parts, manufacturing companies in the automotive, aircraft and mechanical engineering sectors as well as research establishments dealing with additive manufacturing methods.

We have already had expressions of interest from business and industry. Skalon is confident that more will follow in the next few months. With his spin-off, he would like to become an important part of the supply chain in additive manufacturing. The young academic is supported by a top-class team.

Christof Sommitsch, head of TU Graz’s Institute of Materials Science, Joining and Forming (IMAT), has taken on the role of supervisor in the project, and the chairman of Junge Wirtschaft Steiermark, Christoph Kovacic, is a mentor.

Skalon receives help in the business development from the head of TU Graz’s Institute of General Management and Organisation (UFO), Stefan Vorbach, as well as from institute staff Martin Glinik and Elisabeth Poandl.

This research area is anchored in the Field of Expertise “Advanced Materials Science“, one of five strategic foci of TU Graz. It is funded by the Austrian Research Promotion Agency (FFG) in the “Spin-off Fellowship“ funding programme.

Mateusz SKALON

mgr. Inz. dr.

TU Graz | Institute of Materials Science, Joining and Forming

Tel.: +43 316 873 4305

E-Mail: mateusz.skalon@tugraz.at

imat.tugraz.at

https://www.ffg.at/en/spin-off-fellowships (Information on the Spin-off Fellowships programme)

https://www.tugraz.at/institutes/imat/home/ (TU Graz | Institute of Materials Science, Joining and Forming)

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

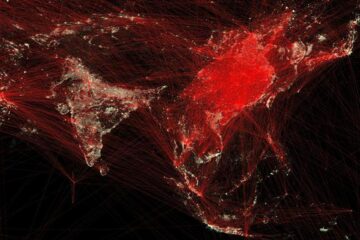

Economies take off with new airports

A global study by an SUTD researcher in collaboration with scientists from Japan explores the economic benefits of airport investment in emerging economies using nighttime satellite imagery. Be it for…

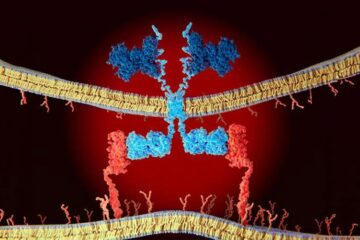

CAR T–cell immunotherapy targets

Pan-cancer analysis uncovers a new class of promising CAR T–cell immunotherapy targets. Scientists at St. Jude Children’s Research Hospital found 156 potential CAR targets across the brain and solid tumors,…

Stony coral tissue loss disease

… is shifting the ecological balance of Caribbean reefs. The outbreak of a deadly disease called stony coral tissue loss disease is destroying susceptible species of coral in the Caribbean…