'Deep learning' casts wide net for novel 2D materials

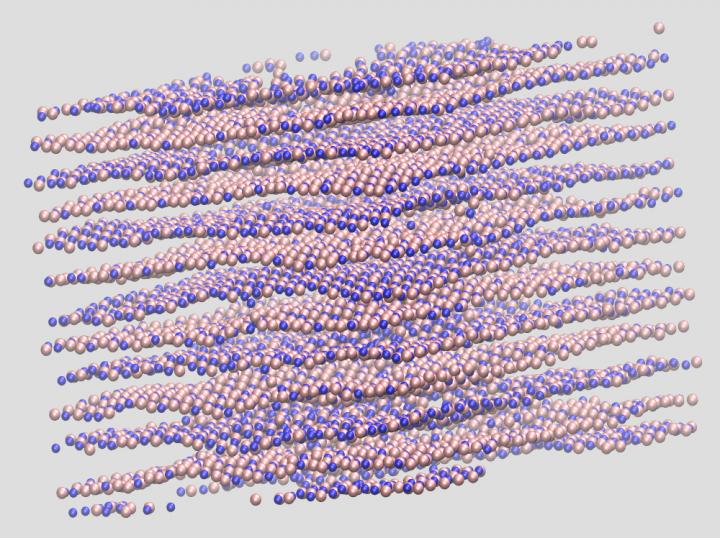

Rice University researchers used a microstructure model of radiation-damaged hexagonal boron nitride to help them study the benefits of deep learning techniques in simulating two-dimensional materials to understand their characteristics. Credit: Prabhas Hundi/Rice University

Scientists are discovering new two-dimensional materials at a rapid pace, but they don't always immediately know what those materials can do.

Researchers at Rice University's Brown School of Engineering say they can find out fast by feeding basic details of their structures to “deep learning” agents that have the power to map the materials' properties. Better yet, the agents can quickly model materials scientists are thinking about making to facilitate the “bottom-up” design of 2D materials.

Rouzbeh Shahsavari, an assistant professor of civil and environmental engineering, and Rice graduate student Prabhas Hundi explored the capabilities of neural networks and multilayer perceptrons that take minimal data from the simulated structures of 2D materials and make “reasonably accurate” predictions of their physical characteristics, like strength, even after they're damaged by radiation and high temperatures.

Once trained, Shahsavari said, these agents could be adapted to analyze new 2D materials with as little as 10 percent of their structural data. That would return an analysis of the material's strengths with about 95 percent accuracy, he said.

“This suggests that transfer learning (in which a deep-learning algorithm trained on one material can be applied to another) is a potential game-changer in material discovery and characterization approaches,” the researchers suggested.

The results of their extensive tests on graphene and hexagonal boron nitride appear in the journal Small.

Since the discovery of graphene in 2004, atom-thick materials have been touted for their strength and range of electronic properties for composites and electronics. Because their atomic arrangements have a significant impact on their properties, researchers often use molecular dynamics simulations to analyze the structures of new 2D materials even before trying to make them.

Shahsavari said deep learning offers a significant speed boost over such traditional simulations of 2D materials and their characteristics, allowing calculations that now take days of supercomputer time to run in hours.

“Because we can build our structure-property maps with only a fraction of the data from graphene or boron nitride molecular dynamics simulations, we see an order of magnitude less computational time to get a full behavior of the material,” he said.

Shahsavari said the lab decided to study graphene and hexagonal boron nitride for their high tolerance to deterioration under high temperatures and in radiation-rich environments, important properties for materials in spacecraft and nuclear power plants. Because the Shahsavari group had already carried out more than 11,000 radiation cascade damage molecular dynamics simulations for another paper on 2D materials, they had incentive to see if they could reproduce their results with a much faster method.

They ran thousands of “deep learning” simulations on 80 combinations of radiation and temperature for hexagonal boron nitride and 48 combinations for graphene, hitting each combination with 31 random doses of simulated radiation. For some, the researchers trained the deep learning agent with a maximum of 45 percent of data from their molecular dynamics study, achieving up to 97 percent accuracy in predicting defects and their effects on the material's characteristics.

Adapting trained agents to different materials, they found, required only about 10 percent of the simulated data, greatly speeding up the process while retaining good accuracy.

“We tried to figure out the corresponding residual strengths of the materials after exposure to extreme conditions, along with all the defects,” he said. “As expected, when the mean temperature or the radiation were too high, the residual strength became pretty low. But that trend wasn't always obvious.”

In some cases, he said, the combined higher radiation and higher temperatures made a material more robust instead of less, and it would help researchers to know that before making a physical product.

“Our deep learning method on the development of structure-property maps could open up a new framework to understand the behavior of 2D materials, discover their non-intuitive commonalities and anomalies, and eventually better design them for tailored applications,” Shahsavari said.

###

The National Science Foundation (NSF) supported the research. Computing resources were supported by the National Institutes of Health, an IBM Shared University Research Award in partnership with Cisco, Qlogic and Adaptive Computing, and the NSF-supported DAVinCI supercomputer administered by Rice's Center for Research Computing and procured in a partnership with Rice's Ken Kennedy Institute for Information Technology.

Read the abstract at https:/

This news release can be found online at https:/

David Ruth, 713-348-6327, david@rice.edu

Mike Williams, 713-348-6728, mikewilliams@rice.edu

Follow Rice News and Media Relations via Twitter @RiceUNews.

Related materials:

Multiscale Materials Laboratory (Shahsavari Lab): http://rouzbeh.

George R. Brown School of Engineering: http://engineering.

Rice Department of Civil and Environmental Engineering: http://www.

Images for download:

https:/

Rice University graduate student Prabhas Hundi, left, and Rouzbeh Shahsavari, an assistant professor of civil and environmental engineering, are using deep learning techniques to speed up simulations of novel two-dimensional materials to understand their characteristics and how they're affected by high temperature and radiation. (Credit: Jeff Fitlow/Rice University)

https:/

Rice University researchers used a microstructure model of radiation-damaged hexagonal boron nitride to help them study the benefits of deep learning techniques in simulating two-dimensional materials to understand their characteristics. (Credit: Prabhas Hundi/Rice University)

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation's top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,962 undergraduates and 3,027 graduate students, Rice's undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for lots of race/class interaction and No. 2 for quality of life by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger's Personal Finance.

Media Contact

More Information:

http://dx.doi.org/10.1002/smll.201900656All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…