3D inks that can be erased selectively

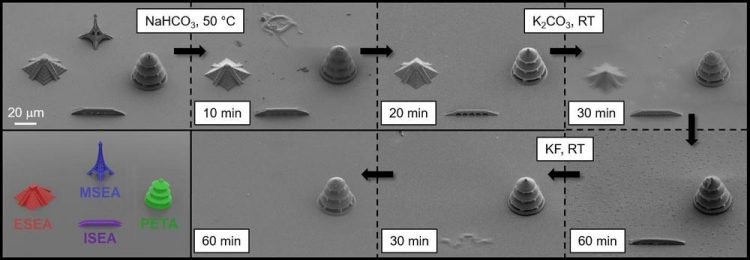

These are three-dimensional microstructures made of various cleavable photoresists. The scanning electron microscopies show the selective degradation of the structures (scaling 20 μm). Credit: Nature Communications

3D printing by direct laser writing enables production of micro-meter-sized structures for many applications, from biomedicine to microelectronics to optical metamaterials. Researchers of Karlsruhe Institute of Technology (KIT) have now developed 3D inks that can be erased selectively.

This allows specific degradation and reassembly of highly precise structures on the micrometer and nanometer scales. The new photoresists are presented in the journal Nature Communications (DOI: 10.1038/s41467-018-05234-0).

3D printing is gaining importance, as it allows for the efficient manufacture of complex geometries. A very promising method is direct laser writing: a computer-controlled focused laser beam acts as a pen and produces the desired structure in a photoresist. In this way, three-dimensional structures with details in the sub-micrometer range can be produced.

“The high resolution is very attractive for applications requiring very precise filigree structures, such as in biomedicine, microfluidics, microelectronics or for optical metamaterials,” say Professor Christopher Barner-Kowollik, Head of the Macromolecular Architectures Group of KIT's Institute for Chemical Technology and Polymer Chemistry (ITCP) and of the Soft Matter Materials Group of Queensland University of Technology (QUT) in Brisbane, Australia, and Dr. Eva Blasco of the ITCP of KIT.

Over a year ago, KIT researchers already succeeded in expanding the possibilities of direct laser writing: the working groups of Professor Martin Wegener at the Institute of Applied Physics (APH) and the Institute of Nanotechnology (INT) of KIT and of Professor Christopher Barner-Kowollik developed an erasable ink for 3D printing. Thanks to reversible binding, the building blocks of the ink can be separated again.

Now, the scientists from Karlsruhe and Brisbane have largely refined their development. As reported in the journal Nature Communications, they have developed several inks, in different colors so to speak, that can be erased independently of each other. This enables selective and sequential degradation and reassembly of the laser-written microstructures.

In case of highly complex constructions, for instance, temporary supports can be produced and removed again later on. It may also be possible to add or remove parts to or from three-dimensional scaffolds for cell growth, the objective being to observe how the cells react to such changes. Moreover, the specifically erasable 3D inks allow for the exchange of damaged or worn parts in complex structures.

When producing the cleavable photoresists, the researchers were inspired by degradable biomaterials. The photoresists are based on silane compounds that can be cleaved easily. Silanes are silicon-hydrogen compounds. The scientists used specific atom substitution for preparing the photoresists. In this way, microstructures can be degraded specifically under mild conditions without structures with other material properties being damaged. This is the major advantage over formerly used erasable 3D inks. New photoresists also contain the monomer pentaerythritol triacrylate that significantly enhances writing without affecting cleavability.

###

Original publication (Open Access):

David Gräfe, Andreas Wickberg, Markus Michael Zieger, Martin Wegener, Eva Blasco, & Christopher Barner-Kowollik: Adding chemically selective subtraction to multi-material 3D additive manufacturing. Nature Communications. 2018. DOI: 10.1038/s41467-018-05234-0

Press contact: Regina Link, Press Officer, Phone: +49 721 608-21158, Email: regina.link@kit.edu

Being “The Research University in the Helmholtz Association,” KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility and information. For this, about 9,300 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 25,500 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life.

This press release is available on the internet at http://www.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…