Laser Technique Shortens Welding Process for Heat-Treatable Steels

Heat-treatable steels are often used for highly stressed construction elements, since they show a high tensile and endurance strength resulting from the heat treatment. In order to weld heat-treatable steels, they must pass through a complex multi-step process. This enables a flawless and stress-resistant weld between both construction elements.

The LZH and the ETP have now developed a process which combines inductive hardening and laser beam welding of multi-part construction elements in one process step. The construction elements are heated to a temperature of over 900°C, the parts are laser welded and then quenched.

The so called “hot welding” immediately reduces tensions occurring during the welding process, so that the danger of cold cracks in the welding seam and a softening of the basic material are avoided.

In order to achieve this, a processing head has been conceived and constructed, which combines inductive heating, the welding process and quench hardening in one step. The processing head consists of a laser processing head, an inductor, a quench shower and a shielding gas nozzle.

In comparison to construction elements which have not been preheated, the processing head used increased the welding depth by 25%. The welding seams and the heat-affected zone show a homogenous hardness distribution. Also, martensitic structures were detected in both areas. After the welding/hardening process has been complete, it is also possible to harden the surface of the construction material using the inductor.

The hot welding process significantly shortens the processing time for heat-treatable steels, and simplifies the process run. In addition, the process simulation developed in the project can be used for an exact calculation of the process.

This research project was funded by the Stiftung Stahlanwendungsforschung, Essen, and coordinated by the Forschungsvereinigung Stahlanwendung e.V., Düsseldorf.

Contact:

Laser Zentrum Hannover e.V.

Michael Botts

Hollerithallee 8

D-30419 Hannover

Germany

Tel.: +49 511 2788-151

Fax: +49 511 2788-100

E-Mail: m.botts@lzh.de

The Laser Zentrum Hannover e.V. (LZH) carries out research and development in the field of laser technology and is supported by the Ministry of Economic Affairs, Labour and Transport of the State of Lower Saxony (Niedersächsisches Ministerium für Wirtschaft, Arbeit und Verkehr).

You can find the LZH press releases with pictures at www.laser-zentrum-hannover.de/en/ (English) under “publications/press releases”

Media Contact

More Information:

http://www.lzh.deAll latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Economies take off with new airports

A global study by an SUTD researcher in collaboration with scientists from Japan explores the economic benefits of airport investment in emerging economies using nighttime satellite imagery. Be it for…

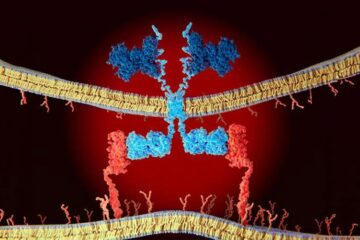

CAR T–cell immunotherapy targets

Pan-cancer analysis uncovers a new class of promising CAR T–cell immunotherapy targets. Scientists at St. Jude Children’s Research Hospital found 156 potential CAR targets across the brain and solid tumors,…

Stony coral tissue loss disease

… is shifting the ecological balance of Caribbean reefs. The outbreak of a deadly disease called stony coral tissue loss disease is destroying susceptible species of coral in the Caribbean…