Safe brakes for vertical axes

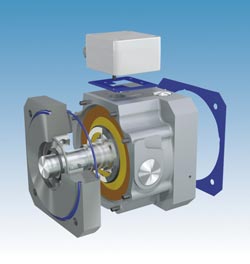

Exploded drawing of the ROBA®-topstop® with the IP 65 design sealing elements<br>

Vertical axis brakes from the ROBA®-topstop® construction series are used worldwide in machines and systems in order to increase safety, in particular in applications with gravity loaded axes. The innovations introduced at the 2011 Hannover Trade Fair now make this brake system even more versatile.

The ROBA®-topstop® vertical axis brake is a safe brake system which, amongst other things, can contribute towards fulfilment of the harmonised standard 13849-1 for the Machinery Directive 2006/42/EC. In order to be able to use these safety brakes on larger servo motors and with Fanuc servo motors in a more flexible manner, this construction series has been extended by two further sizes. Size 175 has been especially conceived for mounting onto Fanuc motors. With a braking torque of up to 400 Nm, the new Size 260 is now capable of securing far larger loads than previously possible.

In many systems, the drive, and therefore the safety brake,

has to be installed directly into the machining chamber due to the constructional design of the drive. The brake is therefore subjected to water spray and various vapours. If these come onto contact with the friction linings, the braking torque may drop to an unpermitted level. In order to cope with these increased demands on the brake protection, all ROBA®-topstop® safety brake sizes are optionally available with protection IP65. Here special seals prevent humidity penetrating the brake.

Experience has shown that ROBA®-topstop® safety brakes are not only activated on emergency switch-offs and when the machine is completely switched off, but also on every cyclic stop. This results in a high quantity of switchings within a short time.

For this reason, mayr ® power transmission have switched to a contactless monitoring system with a proximity sensor for the release monitoring system.

This system is impact-resistant, shock-resistant, magnetic field-resistant and completely wear-free. In addition, it is extremely reliable (Reliability characteristic: MTBF value > 5000 years). This means that the inductive release monitoring system is far superior to the mechanical release monitoring system with microswitch previously used, which worked based on contact, in all ambient conditions.

Chr. Mayr GmbH + Co.KG

Eichenstraße 1, 87665 Mauerstetten

Tel. 08341/804-0, Fax 08341/804-421

E-Mail: info@mayr.de

Media Contact

More Information:

http://www.mayr.comAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Trotting robots reveal emergence of animal gait transitions

A four-legged robot trained with machine learning by EPFL researchers has learned to avoid falls by spontaneously switching between walking, trotting, and pronking – a milestone for roboticists as well…

Innovation promises to prevent power pole-top fires

Engineers in Australia have found a new way to make power-pole insulators resistant to fire and electrical sparking, promising to prevent dangerous pole-top fires and reduce blackouts. Pole-top fires pose…

Possible alternative to antibiotics produced by bacteria

Antibacterial substance from staphylococci discovered with new mechanism of action against natural competitors. Many bacteria produce substances to gain an advantage over competitors in their highly competitive natural environment. Researchers…