Ultra-short laser pulses for science and industry

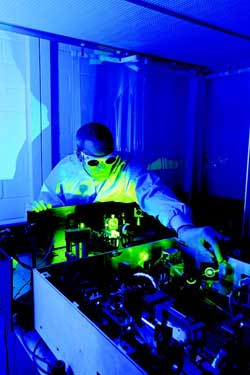

Adjustment of a picosecond laser.<br>Picture Source: Fraunhofer Institute for Laser Technology ILT, Aachen, Germany.<br>

The prize was awarded during the annual meeting of the Fraunhofer Society on May 8, 2012 in Stuttgart in recognition of its outstanding cross-location, multi-disciplinary collaboration on the laser platform for scaling the power of ultra-short laser pulses.

Laser technology uses light. Light can be rapidly and precisely deflected, shaped and focused. If we pulse laser light and continuously reduce the pulse duration, the laser tool works even more precisely. A benefit: The material being processed heats up less and less. High-power, ultra-short pulses, then, are the ideal solution for medical applications, in brain surgery for instance, as the cerebral membrane is not damaged.

Or for removing tumor tissue in order to conserve the surrounding tissue and blood vessels. Yet this precision technology is also valued in the processing of materials, glass for instance: Lasers are able to cut narrow speaker ports in smartphone displays. For years, ultra-short laser pulses have been used for the extremely precise and gentle processing of highly-sensitive materials. Until now though, they have often lacked in power. The newly developed laser platform solves this problem with the INNOSLAB booster as its core. Four mirrors surround a laser crystal plate – the slab.

A pump jet enters at the two opposite sides of the slab. The mirrors are repeatedly deflected to allow ultra-short laser pulses to keep passing the slab. Each time they do, energy is transmitted from the pump jet to the laser pulse until the required power is achieved. This platform was developed by the Fraunhofer institute for Laser Technology ILT in Aachen and refined further together with several partners from industry and science: the chair for laser technology at RWTH Aachen University, the Max Planck institute for Quantum Optics MPQ in Munich and the companies Jenoptik AG, EdgeWave and Amphos – the last two being ILT spin-offs. To develop new markets for laser systems with ultra-short wavelengths, the team of developers had to increase the mean laser output of ultra-short pulse beam sources – up to several hundred watts.

Because higher power makes higher production volumes in business and shorter measuring times during scientific experiments possible. Between 2008 and 2011, two joint projects revolved around developing the new beam source: The aim of the PIKOFLAT project, supported by the Federal Ministry for Education and Research BMBF, was to structure pressure tools and embossing dies. The goal was to reduce processing times while significantly increasing quality.

One of the results of this project is the production of embossing rollers that are used to create extremely fine artificial leather surfaces for the automotive industry. In the second joint project, KORONA, Fraunhofer collaborated closely with the Max Planck Institute for Quantum Optics in Garching near Munich and with RWTH Aachen University. The scientists jointly developed a compact beam source whose extremely short-wave light makes it possible to examine nano-structures.

Stifterverband Science Prize

In 1920, representatives from the business world established the Stifterverband at the suggestion of German academies, universities and scientific associations. Its re-foundation after the Second World War is closely linked with the re-foundation of the »Notgemeinschaft der deutschen Wissenschaft« [Emergency Association of German Science] on 11 January 1949. The Stifterverband is still considered to be the mediator between industry and science today. For ten years, the organization has awarded the Fraunhofer Gesellschaft with a prize worth 50,000 euro. The prize is awarded in recognition of outstanding joint applied research projects, on which Fraunhofer institutes work together with businesses and/or other research organizations (article 1). This and the prize „Technik für den Menschen“ [prize for human-centered technology] are awarded in alternate years.

Contacts at the Fraunhofer ILT

If you have any questions regarding this topic, please feel free to contact our experts:

Dipl.Ing Hans-Dieter Hoffmann

Competece Area Manager Lasers and Laser Optics

Phone +49 241 8906-206

hansdieter.hoffmann@ilt.fraunhofer.de

Dr. Peter Rußbüldt

Group Manager Ultrafast Lasers

Phone +49 241 8906-303

peter.russbueldt@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen

Phone +49 241 8906-0

Fax +49 241 8906-121

Media Contact

More Information:

http://www.ilt.fraunhofer.deAll latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…