The crack as a tool

Glass is a versatile, popular material for a wide range of applications. Cutting the glass is key to obtaining high-quality products. In the conventional process used to cut flat glass, a small cutter wheel scores a line into the glass. Pressure is then applied to the glass along this line so that it breaks.

Unfortunately, glass splinters may come off in the process, producing defects known as micro-cracks. The glass consequently needs to be reworked by grinding and polishing, which costs time and money. Nonetheless, damages may remain in the glass that reduce its strength.

A great deal of time and money, limited design options – reason enough to develop a better, more effective process for separating glass. In a project funded by the Federal Ministry of Education and Research (BMBF), Dr. Rainer Kübler has been working with his five-strong team on a laser-induced stress separation process for flat glass that causes minimal damage. Dr. Rainer Kübler has been awarded the Joseph-von-Fraunhofer Prize 2008 for his work.

So what do the Fraunhofer scientists do that is different? Instead of scoring the glass mechanically, they do it by applying stress. “We have to heat the glass along the required separation line without damaging it,” explains Dr. Kübler. “We do it with a CO2 laser.” The second part of the secret is to shock-cool the glass by means of a cooling nozzle following right behind the laser beam, blowing cold air onto a specific area of the glass. The temperature difference creates a stress field and, in turn, a crack. Then the thermal crack introduced into the surface by this process is opened by bending the glase plate until it separates. Extensive experience and numerical simulation have helped to manage the process and particularly the crack – to produce the crack in a controlled manner and use it as a tool. “Our process has enabled us to produce extremely high-quality glass edges. And flawless, smooth edges mean firmer glass,” says Dr. Kübler. The stability of the edges determines the strength of the entire pane.

All of this opens up entirely new applications for the use of glass panes in architecture. Thanks to the flawless edges, the installed glass panes can be made thinner without sacrificing any of their reliability. And Grenzebach, the development partner, is a global player in glass production technology, providing the new process with ready access to a global market.

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Targeted use of enfortumab vedotin for the treatment of advanced urothelial carcinoma

New study identifies NECTIN4 amplification as a promising biomarker – Under the leadership of PD Dr. Niklas Klümper, Assistant Physician at the Department of Urology at the University Hospital Bonn…

A novel universal light-based technique

…to control valley polarization in bulk materials. An international team of researchers reports in Nature a new method that achieves valley polarization in centrosymmetric bulk materials in a non-material-specific way…

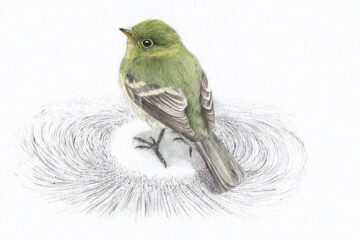

How evolution has optimised the magnetic sensor in birds

The magnetic sense of migratory birds is probably based on the protein cryptochrome 4, and a genetic study has now provided further support for this theory. A team of researchers…